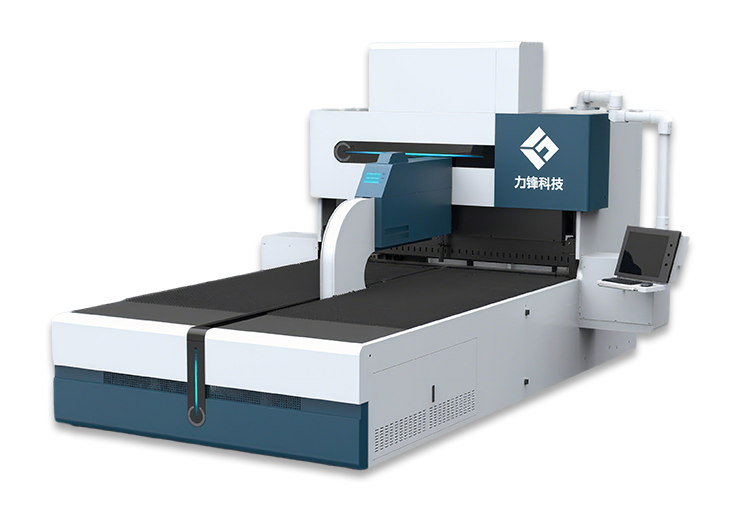

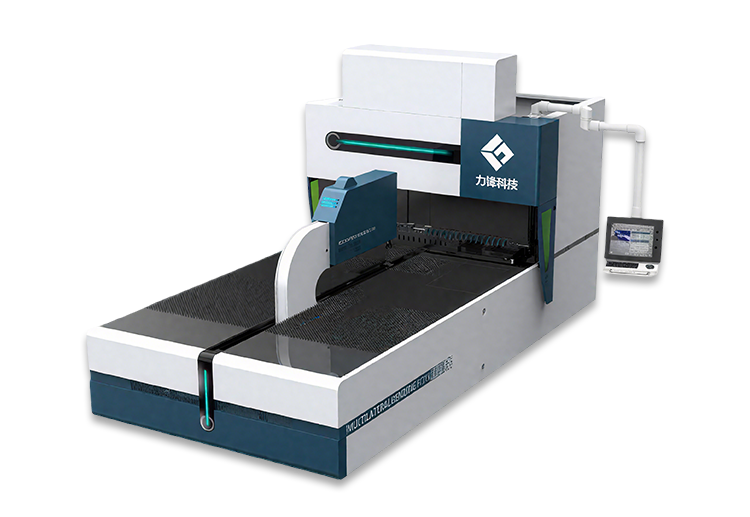

Product advantage

1. Sturdy and Stable Frame Structure—The main frame is carefully made of high-quality carbon steel plates through welding process, with extremely high structural rigidity and stability. It lays a solid foundation for the reliable operation of the equipment under high-intensity and long-time working conditions, and ensures the high precision and reliability of the equipment during processing.

2. Innovative Universal Bending Mold—Equipped with a universal all-purpose bending mold, this mold has intelligent automatic adaptation capability and can perform efficient bending processing on sheet metal parts with various complex geometric shapes. No frequent mold replacement is required, which greatly improves production efficiency and realizes seamless connection from single-product production to mass production, fully reflecting the organic integration of high performance, automatic bending and flexible processing.

3. Optimized Servo Motor Working Condition—The working condition of the servo motor is deeply optimized in the design. Through a series of advanced technical means, the servo motor is guaranteed to maintain a stable and efficient working state under different load and operation conditions, further improving the overall processing performance and stability of the equipment.

4. Nitrogen Balance System—The vertical axis is equipped with a nitrogen balance system. This innovative design can accurately and effectively balance the load of the machine spindle, significantly reducing the wear and fatigue of the spindle during operation, greatly improving the service life of the machine. It enables the machine to perform processing in a high-speed and high-precision state stably for a long time, providing long-term and reliable production guarantee for enterprises.

5. Advanced CNC Operating System—It is equipped with the latest independently developed CNC operating system, which has a user-friendly human-machine interface and simple and intuitive operation. From the setting of processing parameters, the planning of process flow to real-time production monitoring, all can be conveniently completed in this system, covering the entire production process comprehensively. It effectively lowers the skill threshold of operators and improves the efficiency of production management.

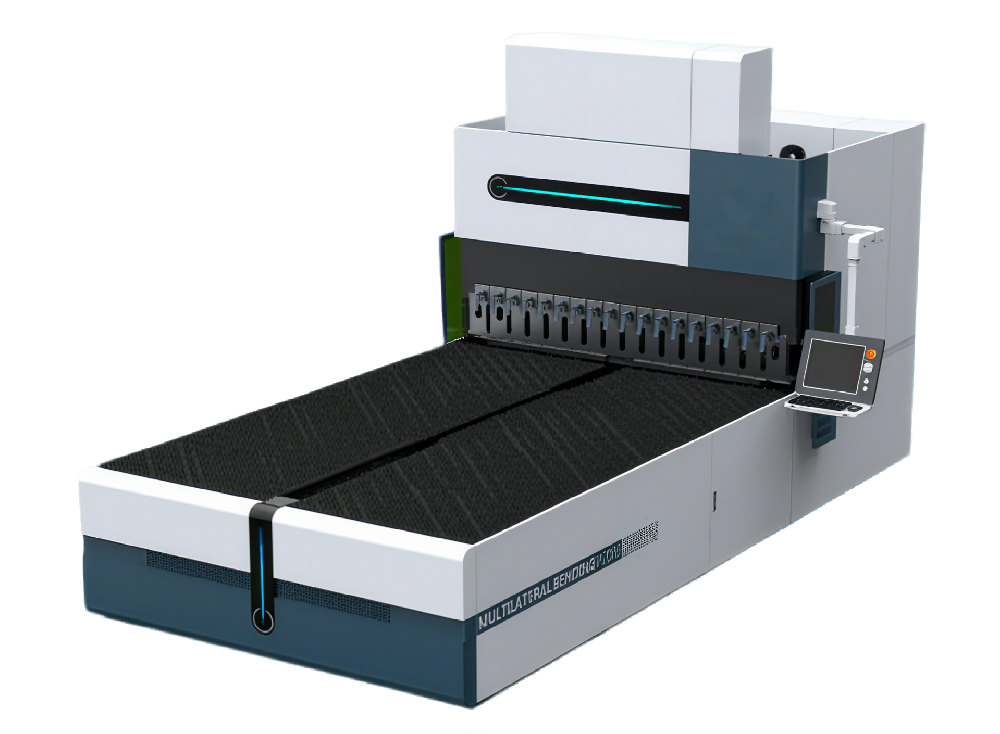

2. Innovative Universal Bending Mold—Equipped with a universal all-purpose bending mold, this mold has intelligent automatic adaptation capability and can perform efficient bending processing on sheet metal parts with various complex geometric shapes. No frequent mold replacement is required, which greatly improves production efficiency and realizes seamless connection from single-product production to mass production, fully reflecting the organic integration of high performance, automatic bending and flexible processing.

3. Optimized Servo Motor Working Condition—The working condition of the servo motor is deeply optimized in the design. Through a series of advanced technical means, the servo motor is guaranteed to maintain a stable and efficient working state under different load and operation conditions, further improving the overall processing performance and stability of the equipment.

4. Nitrogen Balance System—The vertical axis is equipped with a nitrogen balance system. This innovative design can accurately and effectively balance the load of the machine spindle, significantly reducing the wear and fatigue of the spindle during operation, greatly improving the service life of the machine. It enables the machine to perform processing in a high-speed and high-precision state stably for a long time, providing long-term and reliable production guarantee for enterprises.

5. Advanced CNC Operating System—It is equipped with the latest independently developed CNC operating system, which has a user-friendly human-machine interface and simple and intuitive operation. From the setting of processing parameters, the planning of process flow to real-time production monitoring, all can be conveniently completed in this system, covering the entire production process comprehensively. It effectively lowers the skill threshold of operators and improves the efficiency of production management.

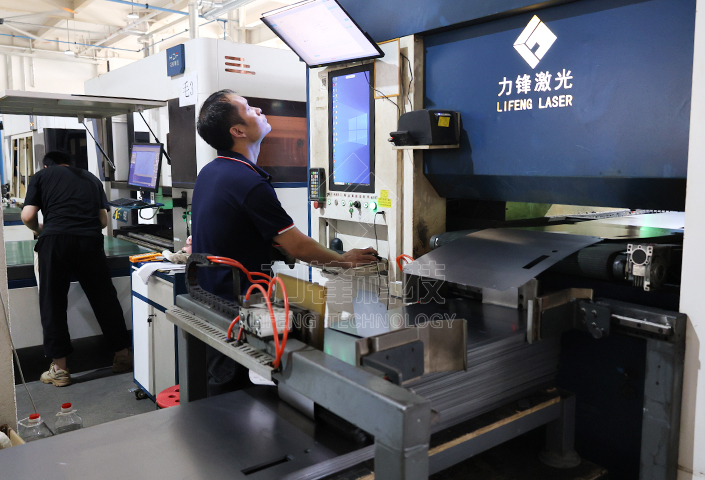

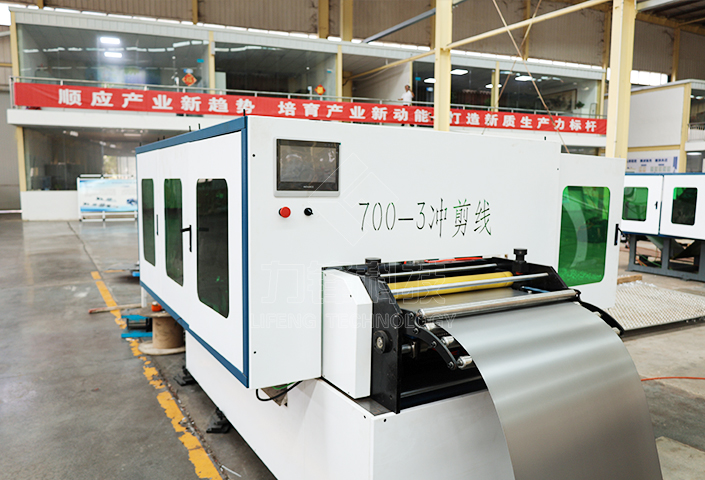

Product show

Product principle

When the Press Arm Bending Center is in operation, first, the advanced CNC operating system receives and parses the processing instructions and parameters input by the operator, and clarifies the geometric shape, size specifications and bending requirements of the sheet metal part to be processed. Subsequently, the universal all-purpose bending mold automatically adjusts to the adapted bending shape and parameters according to the preset instructions. At the same time, the main frame welded with high-quality carbon steel plates provides stable support for the entire processing process by virtue of its good rigidity and stability.

After the sheet metal part to be processed is accurately positioned, the power system of the equipment drives the press arm to press down, and the bending forming of the sheet metal part is realized under the action of the bending mold. During this process, the nitrogen balance system equipped on the vertical axis monitors and adjusts the load of the machine spindle in real time, ensuring the stable operation of the spindle, reducing the vibration and wear caused by uneven load, thus guaranteeing the processing precision and the service life of the machine. The servo motor precisely controls the speed and displacement of each moving part according to the instructions of the CNC system, realizing high-precision processing of the sheet metal part. The entire processing process is carried out in an orderly manner under the unified coordination and monitoring of the CNC operating system. The operator can check the processing status in real time through the user-friendly human-machine interface and make necessary adjustments and interventions in a timely manner until the processing task of the sheet metal part that meets the requirements is completed.

After the sheet metal part to be processed is accurately positioned, the power system of the equipment drives the press arm to press down, and the bending forming of the sheet metal part is realized under the action of the bending mold. During this process, the nitrogen balance system equipped on the vertical axis monitors and adjusts the load of the machine spindle in real time, ensuring the stable operation of the spindle, reducing the vibration and wear caused by uneven load, thus guaranteeing the processing precision and the service life of the machine. The servo motor precisely controls the speed and displacement of each moving part according to the instructions of the CNC system, realizing high-precision processing of the sheet metal part. The entire processing process is carried out in an orderly manner under the unified coordination and monitoring of the CNC operating system. The operator can check the processing status in real time through the user-friendly human-machine interface and make necessary adjustments and interventions in a timely manner until the processing task of the sheet metal part that meets the requirements is completed.

Technical specifications

| Machine Model | LF-P-1500 | LF-P-2100 | LF-P-2600 |

|---|---|---|---|

| Feeding method | Pressure arm type | ||

| Max bending size | 1500×1250mm | 2100×1500mm | 2600×1500mm |

| Max bending height | 170mm | ||

| Min forming size (single side) | 210mm | ||

| Bending angle | 0-180° | ||

| Standard axes | 12-15 axes | ||

| Loading device | Optional | ||

| Unloading device | Optional | ||

| Rated voltage | 380v/50Hz | ||

| Hinge knife | Optional | ||

| Standard bending thickness | Stainless steel 0.3-1.2mm | Iron plate 0.3-1.5mm | Aluminum plate 0.3-2.0mm |

Hot sale

CORE EQUIPMENTCUSTOMER CASE

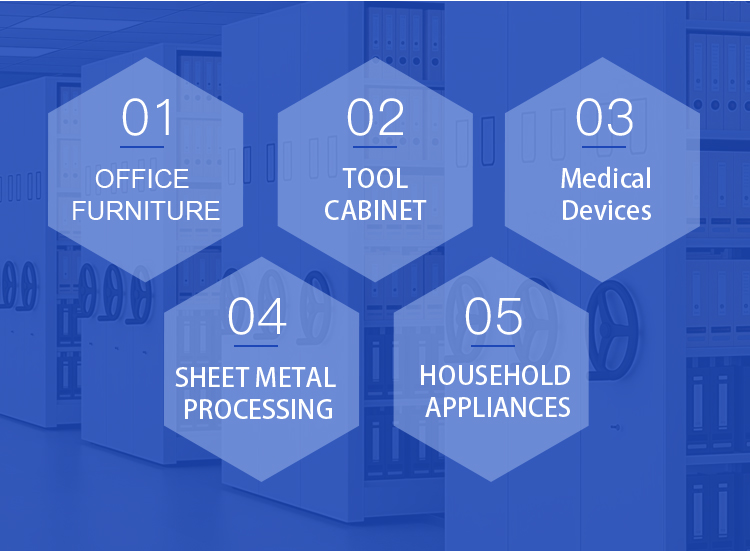

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult