Product advantage

1.Solves the pain point of "weak load-bearing, poor precision and short service life" — Adopts special high-load lead screws, guide rail structures and imported bearings, with strong load-bearing capacity and high positioning precision, making the machine's rigidity, precision retention and reliability close to perfect.

2.Addresses the problem of "design defects and insufficient performance" — Introduces advanced design concepts and scientific design methods to make up for the unavoidable shortcomings of traditional design and improve the comprehensive performance of the equipment.

3.Resolves the issue of "low efficiency and poor consistency" — Fast and simple programming, supporting multi-axis concurrent linkage and rapid feed positioning, with bending efficiency, precision and consistency significantly better than traditional hydraulic bending machines.

4.Overcomes the difficulty of "high pollution and high energy consumption" — No need for hydraulic oil, environmentally friendly and pollution-free; saves about 80% energy compared with traditional equipment, reducing production energy consumption costs.

2.Addresses the problem of "design defects and insufficient performance" — Introduces advanced design concepts and scientific design methods to make up for the unavoidable shortcomings of traditional design and improve the comprehensive performance of the equipment.

3.Resolves the issue of "low efficiency and poor consistency" — Fast and simple programming, supporting multi-axis concurrent linkage and rapid feed positioning, with bending efficiency, precision and consistency significantly better than traditional hydraulic bending machines.

4.Overcomes the difficulty of "high pollution and high energy consumption" — No need for hydraulic oil, environmentally friendly and pollution-free; saves about 80% energy compared with traditional equipment, reducing production energy consumption costs.

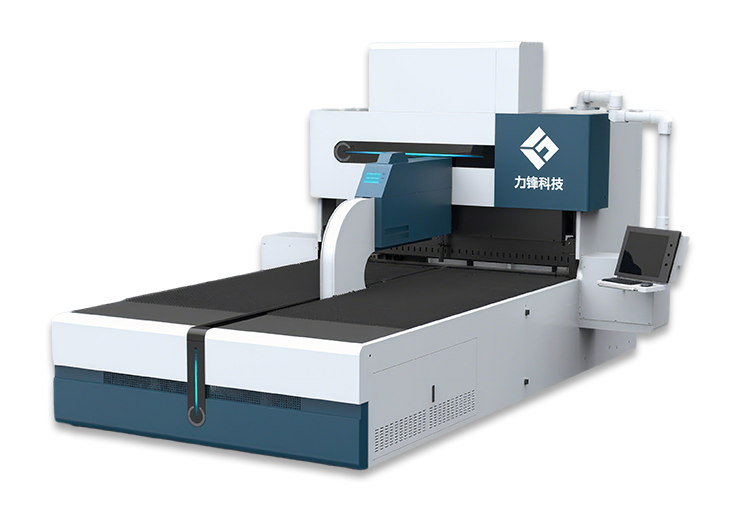

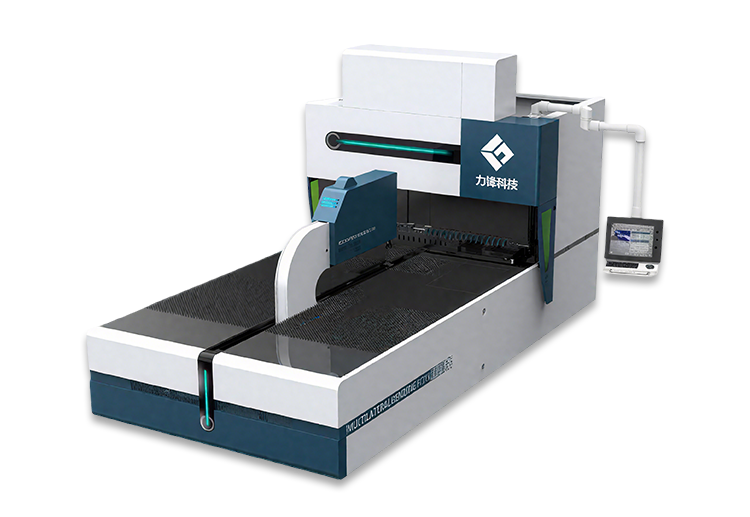

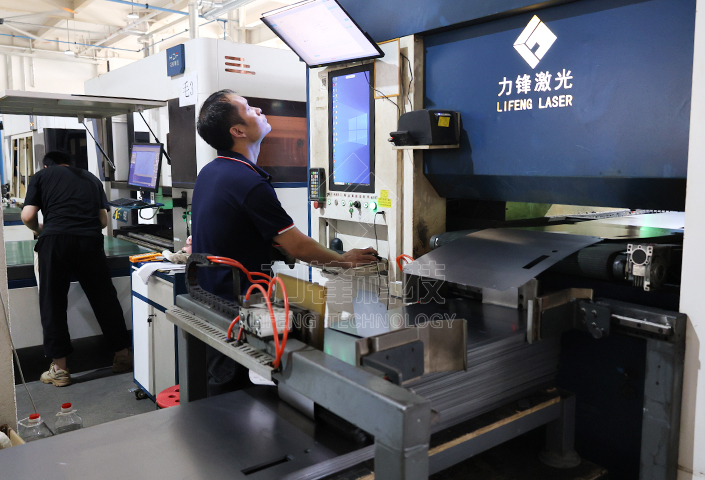

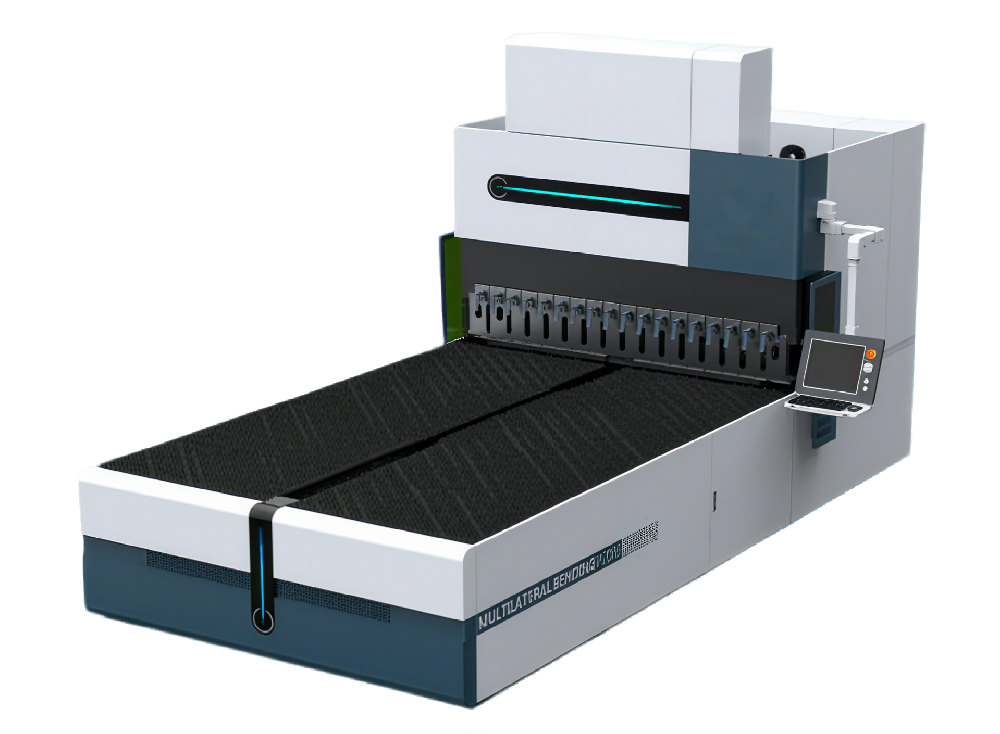

Product show

Product principle

High-precision transmission foundation — High-load lead screws, guide rails and imported bearings work together to ensure accurate positioning and stable load-bearing during equipment operation, providing transmission support for high-precision bending.

Efficient linkage bending — After the CNC system receives programming instructions, it controls the concurrent linkage of multiple axes, drives the bending mechanism to quickly feed and position, and accurately completes the sheet metal bending action, improving processing efficiency and consistency.

Environmentally friendly and energy-saving operation — Adopts all-electric servo drive, no need for hydraulic oil circulation system, avoiding oil pollution; at the same time, through optimized energy consumption design, it significantly reduces energy consumption compared with traditional hydraulic bending machines, realizing an environmentally friendly and energy-saving processing process.

Efficient linkage bending — After the CNC system receives programming instructions, it controls the concurrent linkage of multiple axes, drives the bending mechanism to quickly feed and position, and accurately completes the sheet metal bending action, improving processing efficiency and consistency.

Environmentally friendly and energy-saving operation — Adopts all-electric servo drive, no need for hydraulic oil circulation system, avoiding oil pollution; at the same time, through optimized energy consumption design, it significantly reduces energy consumption compared with traditional hydraulic bending machines, realizing an environmentally friendly and energy-saving processing process.

Technical specifications

| Machine Model | LF-S-2100 |

| Feeding Method | Vacuum Cup Type |

| Maximum Bending Size | 2100x1500mm |

| Maximum Bending Height | 170mm |

| Minimum Single-Side Forming Size | 210mm |

| Bending Angle (°) | 0-180° |

| Standard Axis Count | 12-15Axes |

| Loading Device | Optional Selection |

| Unloading Device | Optional Selection |

| Rated Voltage | 380v/50Hz |

| Hinge Cutter | Optional Selection |

| Standard Bending Thickness | Stainless Steel (0.3-1.2mm)、Cold-Rolled Steel Plate (0.3-1.5mm)、Aluminum Plate (0.3-2.0mm) |

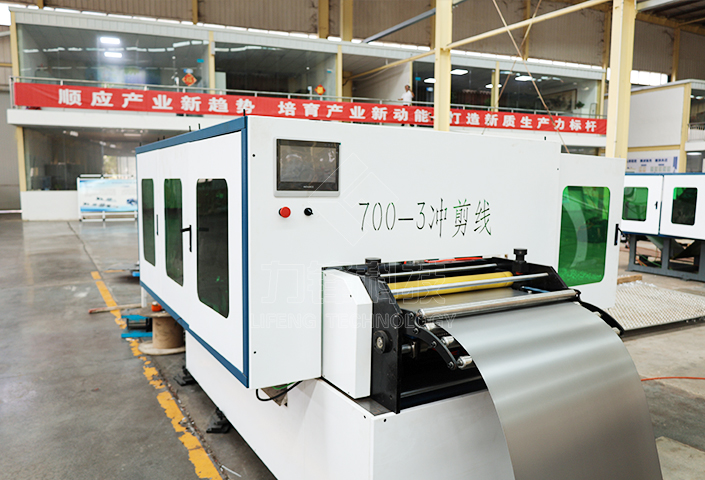

Hot sale

CORE EQUIPMENTCUSTOMER CASE

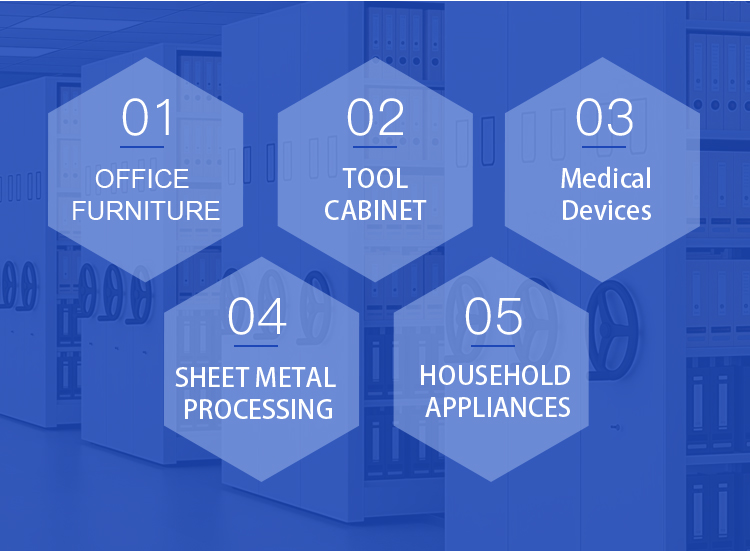

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult