Product advantage

Addresses the problem of "low batch efficiency and poor adaptability" — Equipped with universal bending molds that automatically adapt to workpieces of various geometric shapes, supporting batch production without frequent mold changes.

Resolves the issue of "short service life and high motor load" — The vertical axis is equipped with a nitrogen balance system, which effectively balances the machine spindle load, improves the servo motor working condition, and significantly extends the equipment service life.

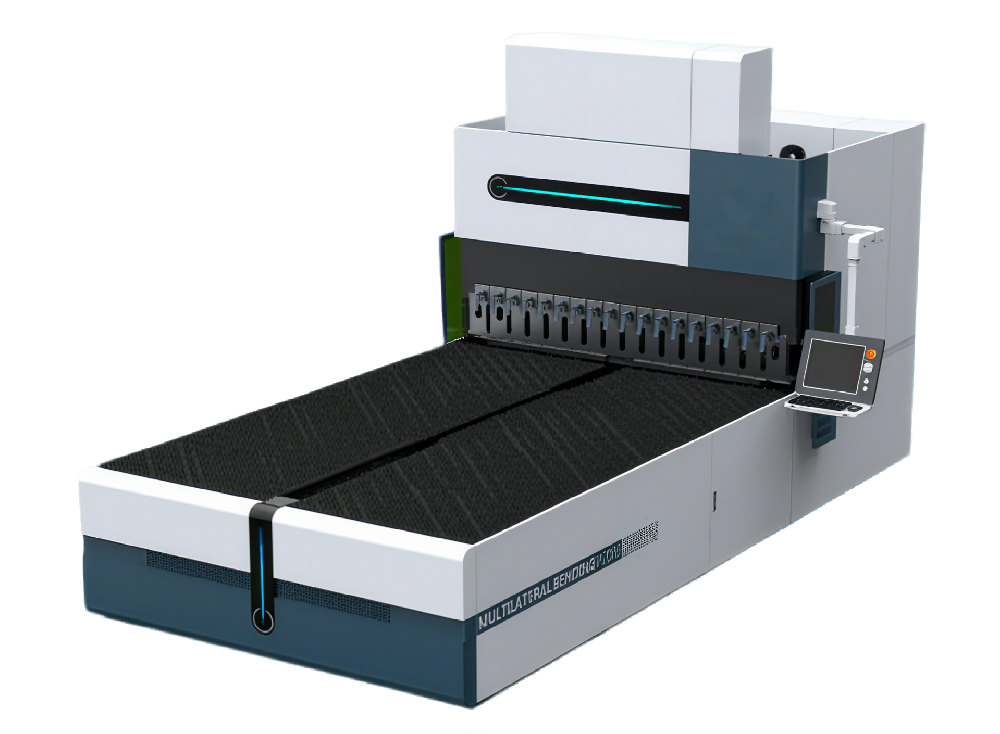

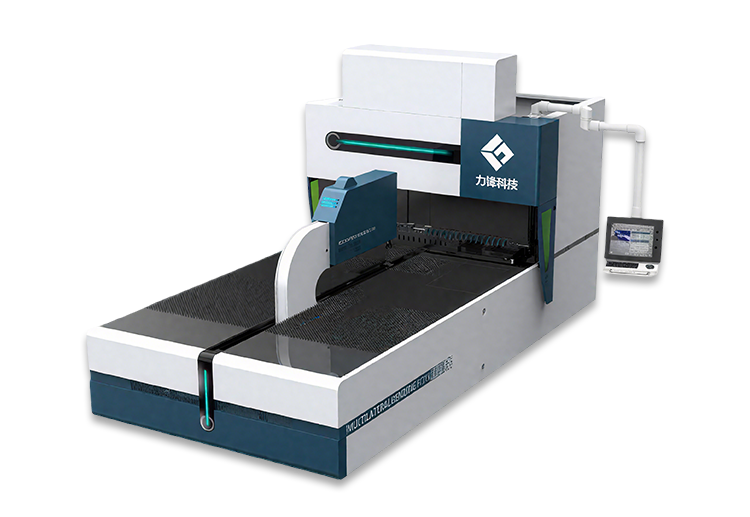

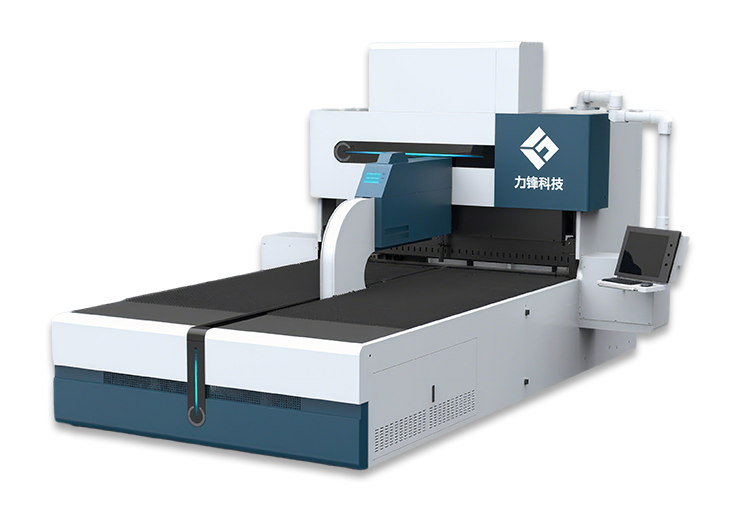

Product show

Product principle

Flexible and efficient processing — Universal molds automatically fit the workpiece geometry; after the CNC system controls the press arm to position the workpiece, it drives the flap mechanism to complete automatic bending, enabling batch production.

Long-term operation guarantee — The nitrogen balance system balances the spindle load in real time, reduces servo motor wear, ensures long-term high-speed and high-precision operation of the equipment, and forms an automated "positioning-bending-unloading" process.

Technical specifications

| Machine Model | LF-P-2100 |

| Feeding Method | Press Arm Type |

| Maximum Bending Size | 2100x1500mm |

| Maximum Bending Height | 170mm |

| Minimum Single-Side Forming Size | 210mm |

| Bending Angle (°) | 0-180° |

| Standard Axis Count | 12-15Axes |

| Loading Device | Optional Selection |

| Unloading Device | Optional Selection |

| Rated Voltage | 380v/50Hz |

| Hinge Cutter | Optional Selection |

| Standard Bending Thickness | Stainless Steel (0.3-1.2mm)、Cold-Rolled Steel Plate (0.3-1.5mm)、Aluminum Plate (0.3-2.0mm) |

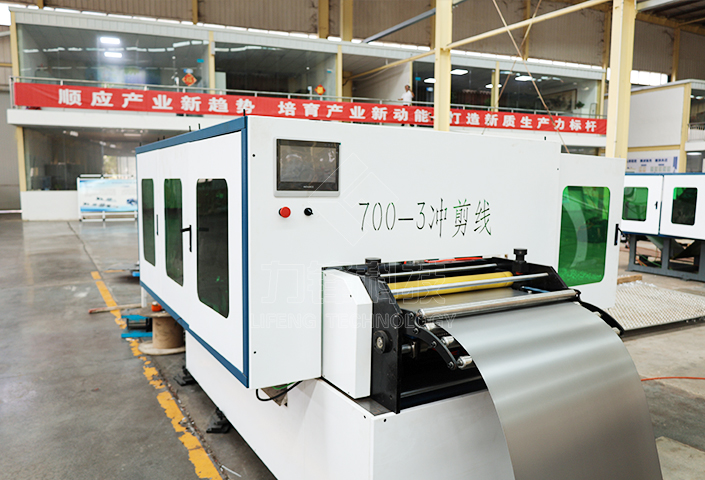

Hot sale

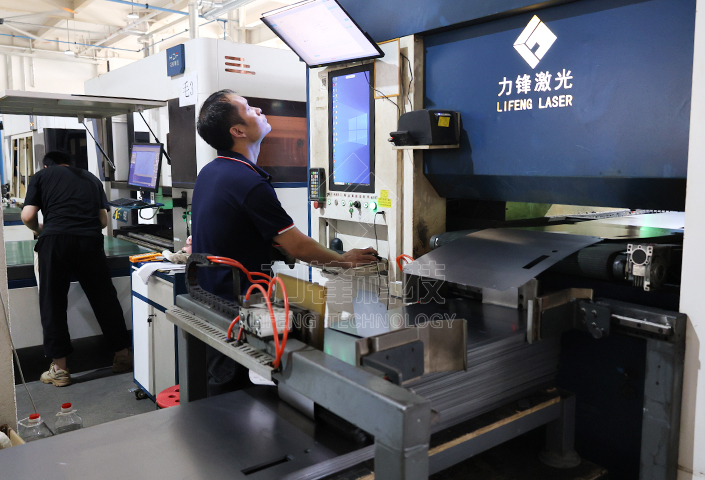

CORE EQUIPMENTCUSTOMER CASE

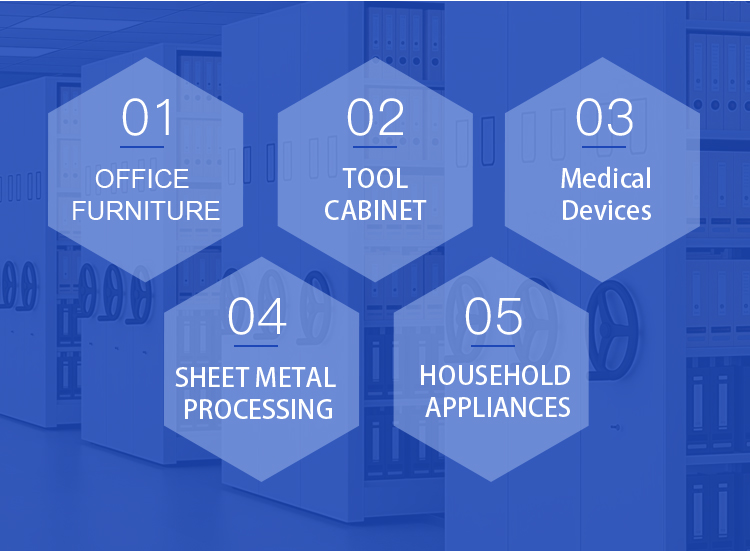

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult