Product advantage

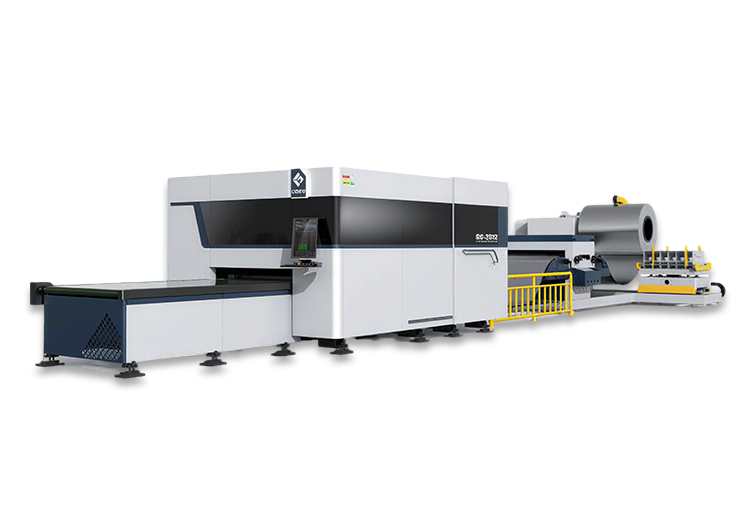

1.Solves the pain point of "slow feeding and low efficiency" — The fully enclosed design combined with automatic feeding function greatly reduces feeding time and improves overall production efficiency.

2.Addresses the problem of "poor precision and low reliability" — Key components such as modularly assembled reducers, gears and racks are from well-known brands, ensuring high-precision operation of the equipment and improving reliability.

3.Resolves the issue of "easy fuselage deformation and poor stability" — The cutting bed undergoes heat treatment to eliminate welding stress, reduce heat input and avoid long-term thermal deformation; the high-strength integral cast aluminum alloy beam has high strength, light weight and good dynamic response.

4.Overcomes the difficulty of "few options and high labor intensity" — The overall modular design provides diverse options; the front blanking area is equipped with a blanking conveying module, which facilitates the conveying of blanked plates and reduces workers' labor intensity.

2.Addresses the problem of "poor precision and low reliability" — Key components such as modularly assembled reducers, gears and racks are from well-known brands, ensuring high-precision operation of the equipment and improving reliability.

3.Resolves the issue of "easy fuselage deformation and poor stability" — The cutting bed undergoes heat treatment to eliminate welding stress, reduce heat input and avoid long-term thermal deformation; the high-strength integral cast aluminum alloy beam has high strength, light weight and good dynamic response.

4.Overcomes the difficulty of "few options and high labor intensity" — The overall modular design provides diverse options; the front blanking area is equipped with a blanking conveying module, which facilitates the conveying of blanked plates and reduces workers' labor intensity.

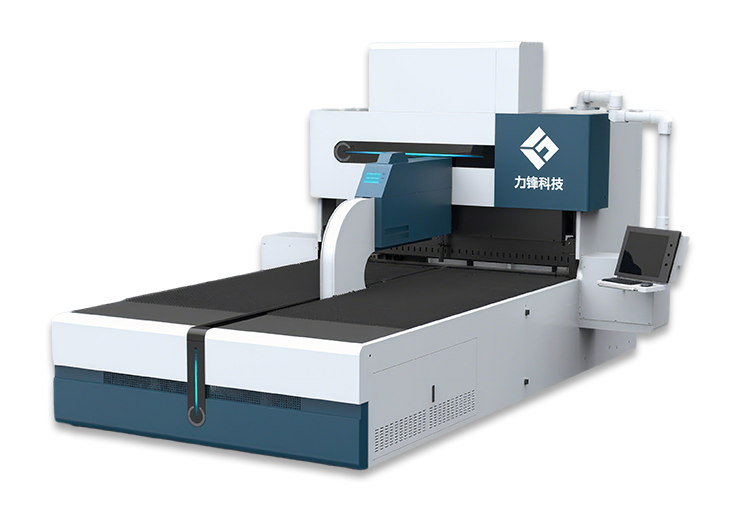

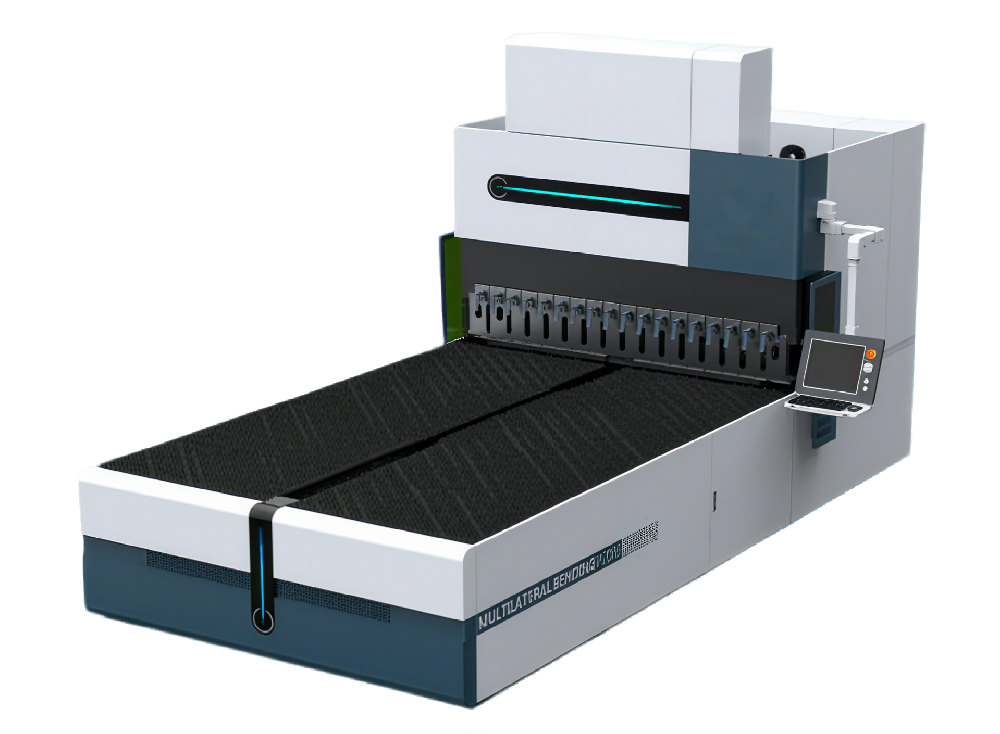

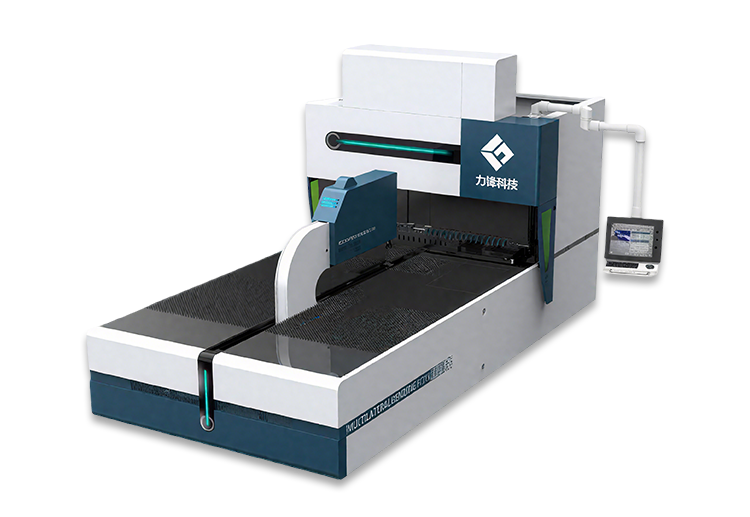

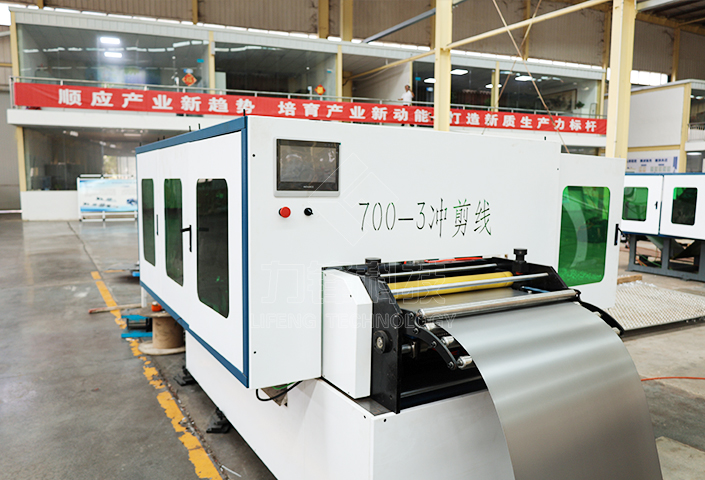

Product show

Product principle

1.Stable cutting foundation — The heat-treated bed eliminates welding stress to avoid deformation; the aluminum alloy beam provides stable support, ensuring accurate positioning of the laser cutting head during operation and laying the foundation for high-precision cutting.

2.Efficient automated processing — The automatic feeding system delivers rough materials to the cutting area, and the CNC system controls the laser cutting head to cut according to the preset program; key components work together to ensure cutting precision and efficiency, and the modular design can be flexibly adjusted according to needs.

3.Convenient blanking and conveying — After cutting, the blanking conveying module in the front blanking area automatically conveys the finished plates to the designated area, reducing manual handling, lowering labor intensity and forming an automated "feeding-cutting-blanking" process.

2.Efficient automated processing — The automatic feeding system delivers rough materials to the cutting area, and the CNC system controls the laser cutting head to cut according to the preset program; key components work together to ensure cutting precision and efficiency, and the modular design can be flexibly adjusted according to needs.

3.Convenient blanking and conveying — After cutting, the blanking conveying module in the front blanking area automatically conveys the finished plates to the designated area, reducing manual handling, lowering labor intensity and forming an automated "feeding-cutting-blanking" process.

Technical specifications

| Machine Model | LF-SC-2513 | LF-SC-2515 | LF-SC-3015 |

| Cutting Area | 2500x1300mm | 2500x1500mm | 3000x1500mm |

| X-Axis Stroke | 1300mm | 1500mm | |

| Y-Axis Stroke | 2500mm | 3000mm | |

| Z-Axis Stroke | 290mm | ||

| Feeding Precision | ±0.05mm | ||

| Minimum Cutting Edge | 1mm | ||

| Leveling Thickness | 0.3-2mm | ||

| Maximum Positioning Speed | 120m/min | ||

| Maximum Acceleration | 1.5G | ||

| Gas Used / Operating Gas | Air / Oxygen / Ammonia | ||

Hot sale

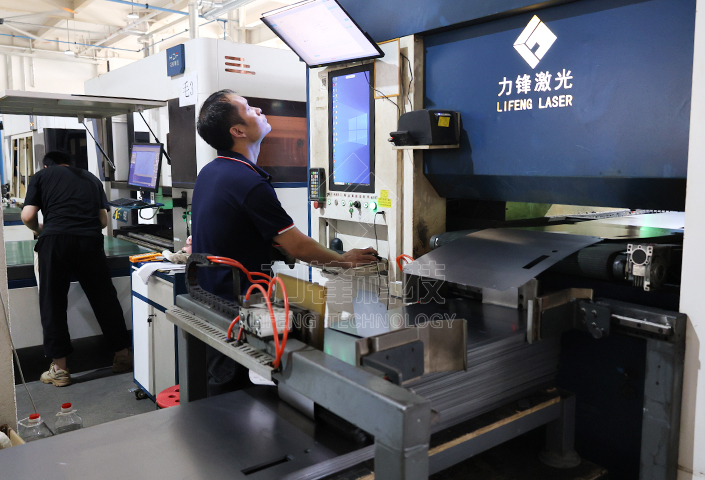

CORE EQUIPMENTCUSTOMER CASE

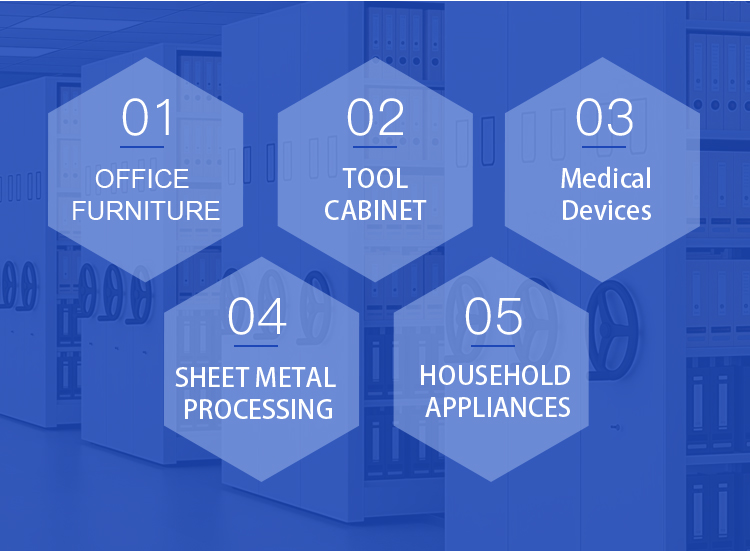

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult