Product advantage

1.Solves the pain point of "long feeding time and low efficiency" — The fully enclosed design combined with automatic feeding function greatly shortens feeding time and improves standard production efficiency.

2.Addresses the problem of "poor precision and low reliability" — Key components such as modularly assembled reducers, gears and racks are selected from well-known brands to ensure standardized high-precision operation of the equipment and improve service reliability.

3.Resolves the issue of "easy fuselage deformation and poor stability" — The cutting bed undergoes heat treatment to eliminate welding stress, reduce heat input and avoid long-term thermal deformation; the high-strength integral cast aluminum alloy beam has the characteristics of beauty, high strength and light weight, with excellent dynamic response.

4.Overcomes the difficulty of "few options and high labor intensity" — The overall modular design provides diverse standard options; the front blanking area is equipped with a blanking conveying module, which facilitates the conveying of blanked plates and reduces workers' labor intensity.

2.Addresses the problem of "poor precision and low reliability" — Key components such as modularly assembled reducers, gears and racks are selected from well-known brands to ensure standardized high-precision operation of the equipment and improve service reliability.

3.Resolves the issue of "easy fuselage deformation and poor stability" — The cutting bed undergoes heat treatment to eliminate welding stress, reduce heat input and avoid long-term thermal deformation; the high-strength integral cast aluminum alloy beam has the characteristics of beauty, high strength and light weight, with excellent dynamic response.

4.Overcomes the difficulty of "few options and high labor intensity" — The overall modular design provides diverse standard options; the front blanking area is equipped with a blanking conveying module, which facilitates the conveying of blanked plates and reduces workers' labor intensity.

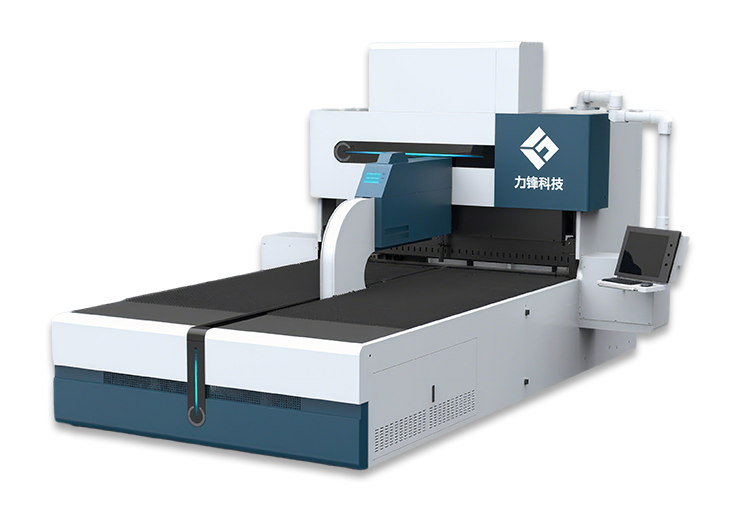

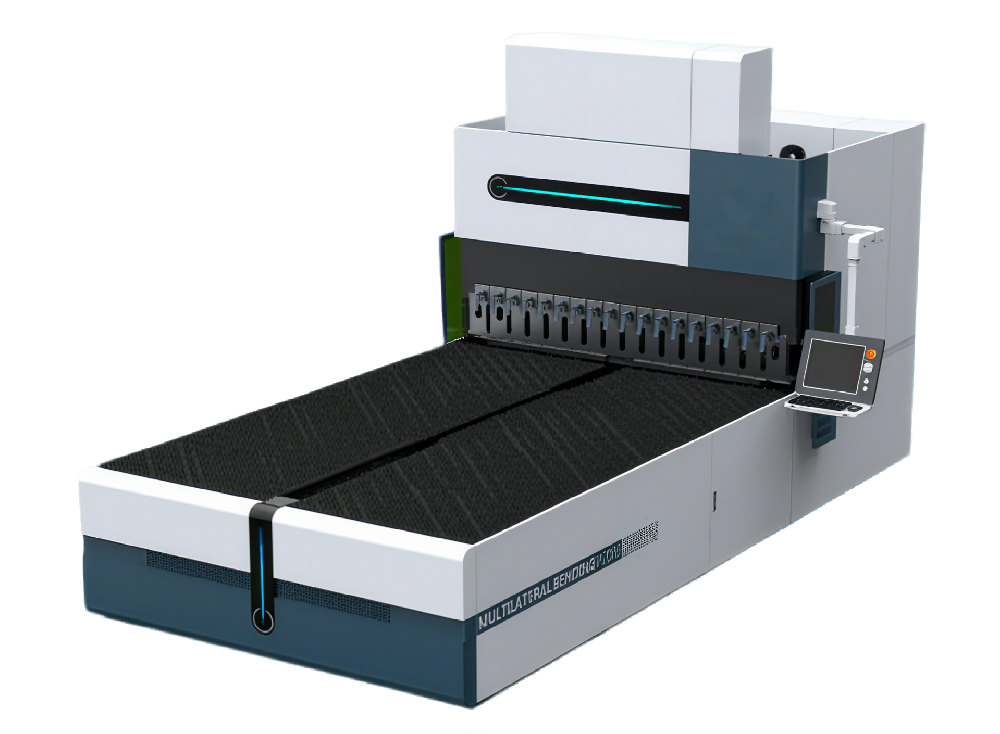

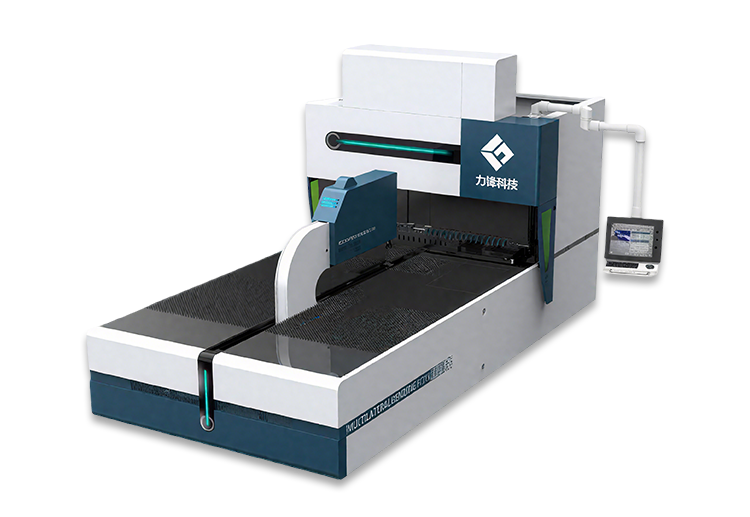

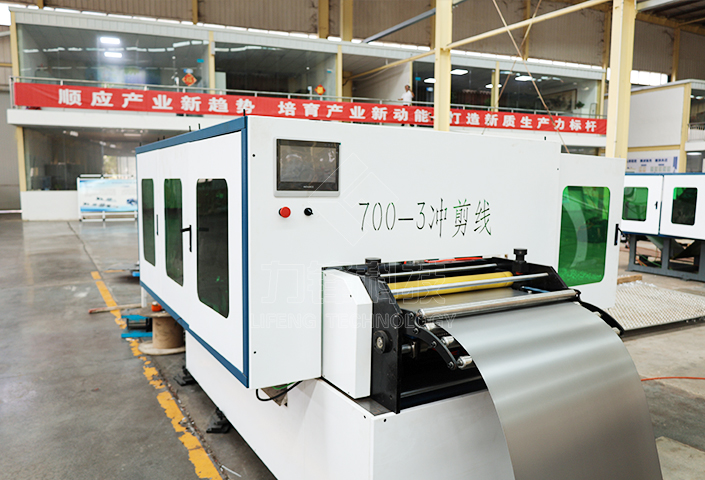

Product show

Product principle

Stable cutting foundation — The heat-treated bed avoids deformation, and the aluminum alloy beam provides stable support to ensure accurate positioning of the laser cutting head during standard operation, laying a solid foundation for high-precision cutting.

Standard automated processing — The automatic feeding system delivers rough materials to the cutting area, and the CNC system controls the laser cutting head to cut according to standard programs; key components work together to ensure standard cutting precision and efficiency, and the modular design can be flexibly adjusted according to needs.

Convenient blanking and conveying — After cutting, the blanking conveying module in the front blanking area automatically conveys the finished plates to the designated area, reducing manual handling, lowering labor intensity and forming a standardized automated "feeding-cutting-blanking" process.

Standard automated processing — The automatic feeding system delivers rough materials to the cutting area, and the CNC system controls the laser cutting head to cut according to standard programs; key components work together to ensure standard cutting precision and efficiency, and the modular design can be flexibly adjusted according to needs.

Convenient blanking and conveying — After cutting, the blanking conveying module in the front blanking area automatically conveys the finished plates to the designated area, reducing manual handling, lowering labor intensity and forming a standardized automated "feeding-cutting-blanking" process.

Technical specifications

| Machine Model | LF-SC-2513 | LF-SC-2515 | LF-SC-3015 |

| Cutting Area | 2500x1300mm | 2500x1500mm | 3000x1500mm |

| X-Axis Stroke | 1300mm | 1500mm | |

| Y-Axis Stroke | 2500mm | 3000mm | |

| Z-Axis Stroke | 290mm | ||

| Feeding Precision | ±0.05mm | ||

| Minimum Cutting Edge | 1mm | ||

| Leveling Thickness | 0.3-2mm | ||

| Maximum Positioning Speed | 120m/min | ||

| Maximum Acceleration | 1.2G | ||

| Gas Used / Operating Gas | Air / Oxygen / Ammonia | ||

Hot sale

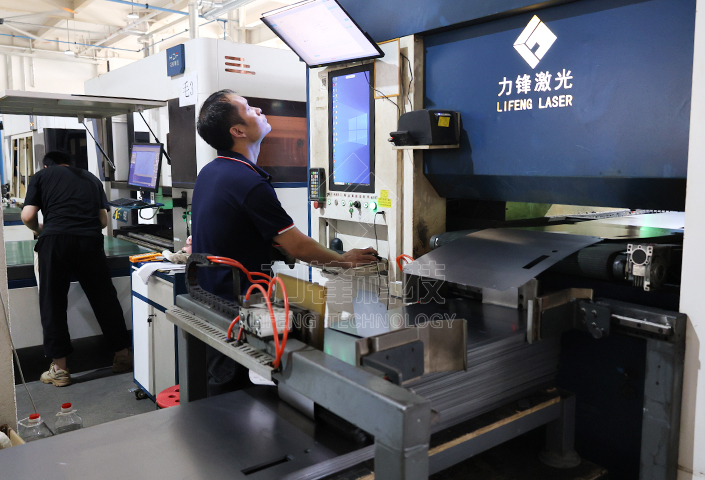

CORE EQUIPMENTCUSTOMER CASE

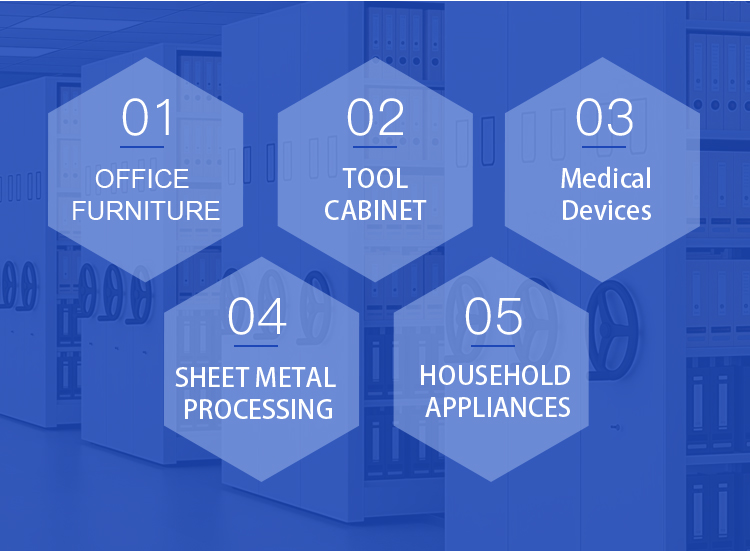

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult