Product advantage

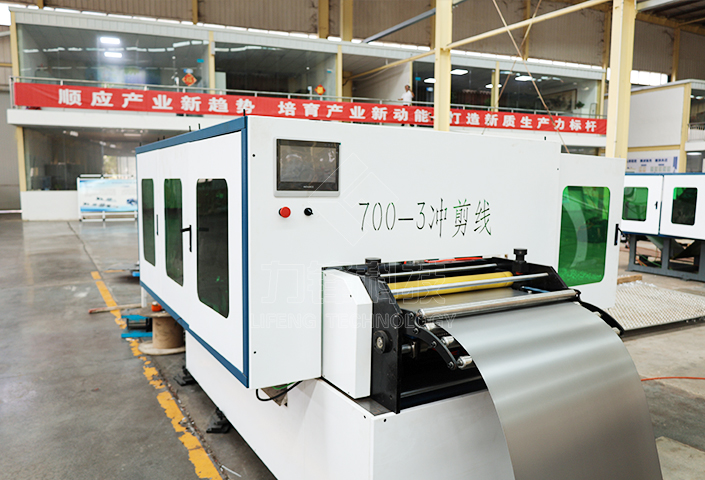

1.Solves the pain point of "poor protection and low safety" — The fully enclosed design combined with safety protection structure improves operation safety and avoids potential risks during cutting.

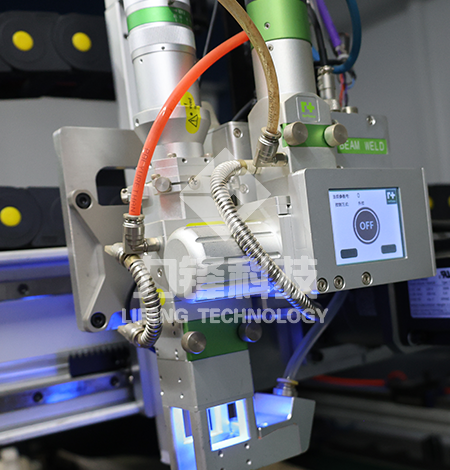

2.Addresses the problem of "low efficiency and poor stability" — Customized RAYTOOLS production line-specific laser head with high efficiency and good stability; permanent magnet linear motor achieves 120M/min idle speed and 1.5G acceleration, greatly improving cutting efficiency.

3.Resolves the issue of "insufficient precision and difficult material saving" — Grating ruler closed-loop control + servo motor feeding with encoder feedback ensures precise feeding; net material cutting design saves more materials, and linear motor module ensures cutting precision under high-speed operation.

4.Overcomes the difficulty of "high pollution and complicated operation" — Full-stroke exhaust pipe with concentrated suction, environmentally friendly and pollution-free; full-process automation of automatic material rack, leveling, feeding, etc., and customized net material cutting system for easy operation, reducing manual intervention.

2.Addresses the problem of "low efficiency and poor stability" — Customized RAYTOOLS production line-specific laser head with high efficiency and good stability; permanent magnet linear motor achieves 120M/min idle speed and 1.5G acceleration, greatly improving cutting efficiency.

3.Resolves the issue of "insufficient precision and difficult material saving" — Grating ruler closed-loop control + servo motor feeding with encoder feedback ensures precise feeding; net material cutting design saves more materials, and linear motor module ensures cutting precision under high-speed operation.

4.Overcomes the difficulty of "high pollution and complicated operation" — Full-stroke exhaust pipe with concentrated suction, environmentally friendly and pollution-free; full-process automation of automatic material rack, leveling, feeding, etc., and customized net material cutting system for easy operation, reducing manual intervention.

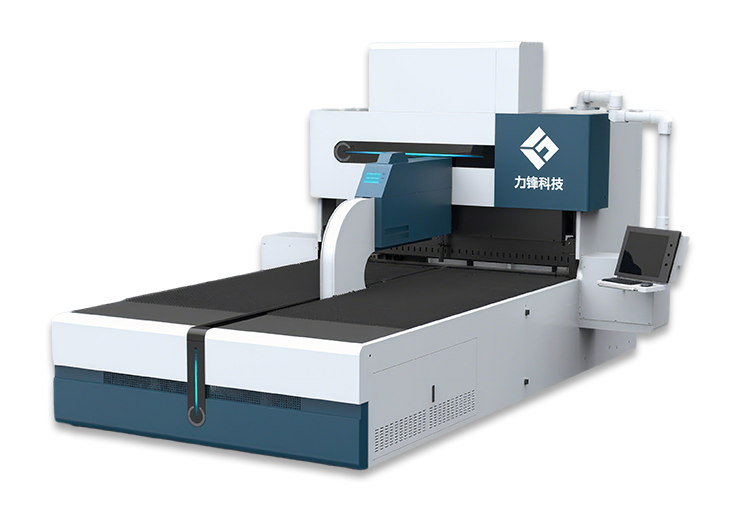

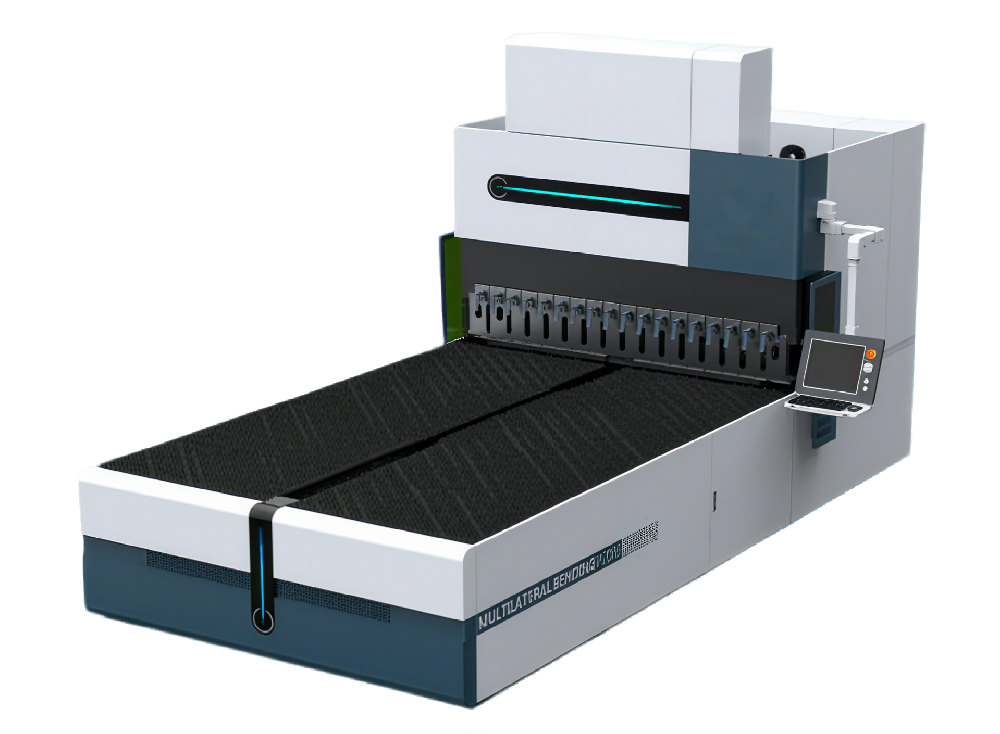

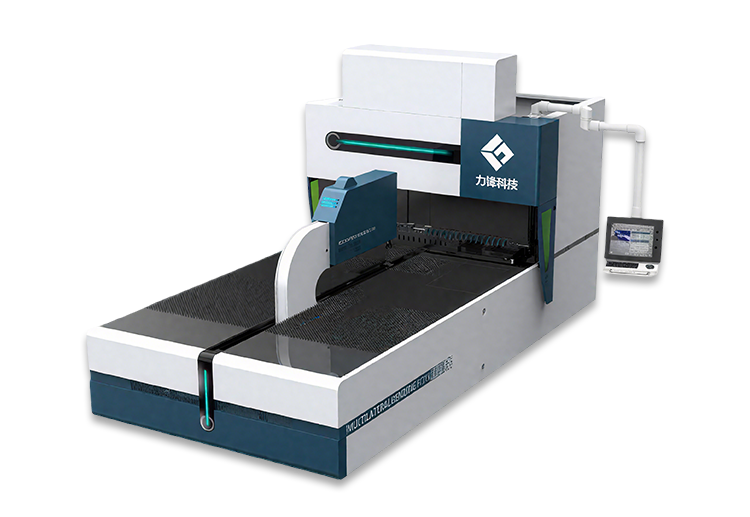

Product show

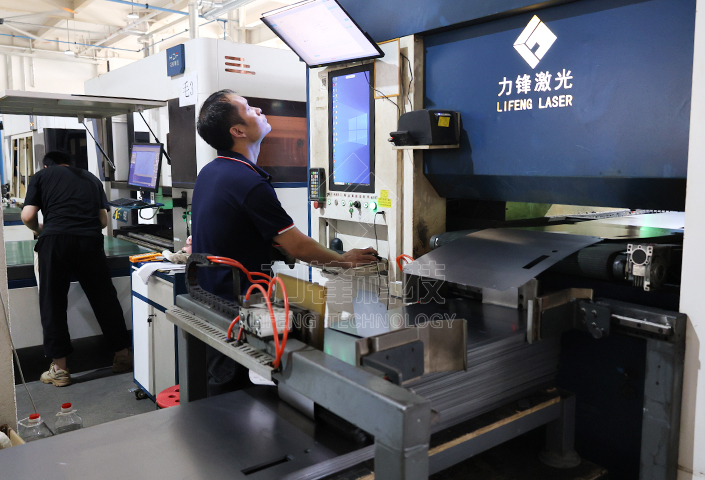

Product principle

Precise drive foundation — Magnetic levitation technology combined with linear motor module, together with grating ruler closed-loop control, realizes high-speed and stable operation of the equipment (120M/min idle speed); meanwhile, servo motor feeding and encoder feedback cooperate to ensure precise feeding and cutting.

Efficient cutting process — The automatic material rack feeds materials to the leveling device, which are accurately fed to the cutting area by the servo motor; the RAYTOOLS laser head completes net material cutting according to the program under the control of the CNC system, with full automation reducing manual operation.

Safety and environmental protection guarantee — The fully enclosed design isolates cutting risks, and the full-stroke exhaust pipe collects cutting fumes in real time to avoid pollution; after cutting, automatic stacking is completed, forming a safe and environmentally friendly automated process of "feeding-leveling-cutting-stacking".

Efficient cutting process — The automatic material rack feeds materials to the leveling device, which are accurately fed to the cutting area by the servo motor; the RAYTOOLS laser head completes net material cutting according to the program under the control of the CNC system, with full automation reducing manual operation.

Safety and environmental protection guarantee — The fully enclosed design isolates cutting risks, and the full-stroke exhaust pipe collects cutting fumes in real time to avoid pollution; after cutting, automatic stacking is completed, forming a safe and environmentally friendly automated process of "feeding-leveling-cutting-stacking".

Technical specifications

| Machine Model | LF-AC-7070 |

| Cutting Area | 700x700mm |

| X-Axis Stroke | 700mm |

| Y-Axis Stroke | 700mm |

| Z-Axis Stroke | 110mm |

| Feeding Precision | ±0.05mm |

| Minimum Cutting Edge | 1mm |

| Leveling Thickness | 0.3-1.5mm |

| Maximum Positioning Speed | 120m/min |

| Maximum Acceleration | 1.5G |

| Gas Used / Operating Gas | Air / Oxygen / Ammonia |

Hot sale

CORE EQUIPMENTCUSTOMER CASE

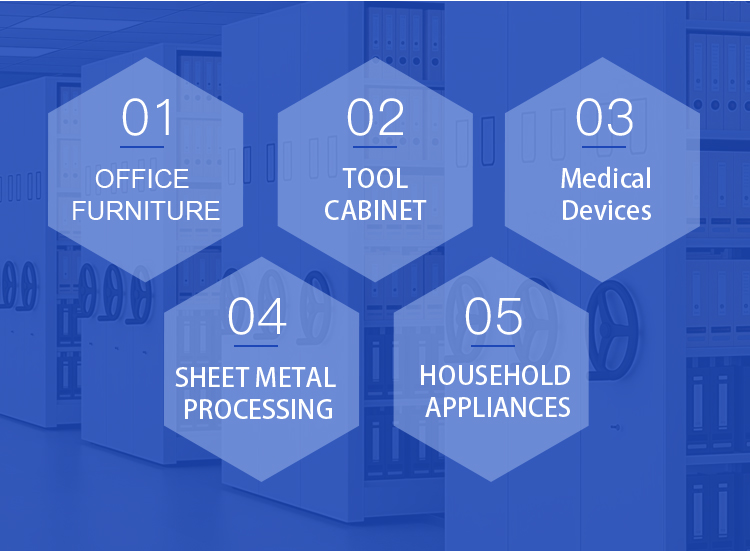

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult