Product advantage

1.“Solves the pain point of "low efficiency & long cycle" — Advanced shearing-punching technology enables completing massive production tasks in a short time, with efficiency far exceeding manual processing and significantly shortening production cycle.

2.”Addresses the problem of "poor adaptability & few categories" — High flexibility design meets processing needs of different products without frequent adjustments, adapting to multi-category sheet metal production.

3.“Resolves the issue of "single scenario & difficult customization" — Customizable according to enterprise needs, adapting to complex and changeable processing scenarios, avoiding equipment unusability due to scenario limitations.

2.”Addresses the problem of "poor adaptability & few categories" — High flexibility design meets processing needs of different products without frequent adjustments, adapting to multi-category sheet metal production.

3.“Resolves the issue of "single scenario & difficult customization" — Customizable according to enterprise needs, adapting to complex and changeable processing scenarios, avoiding equipment unusability due to scenario limitations.

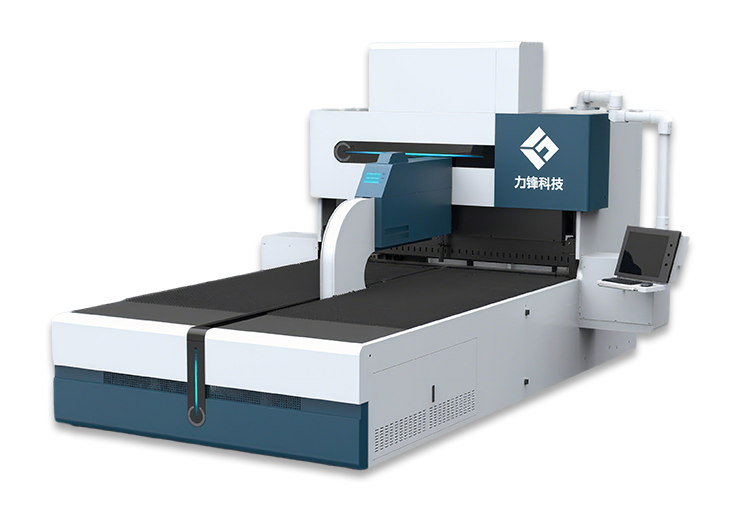

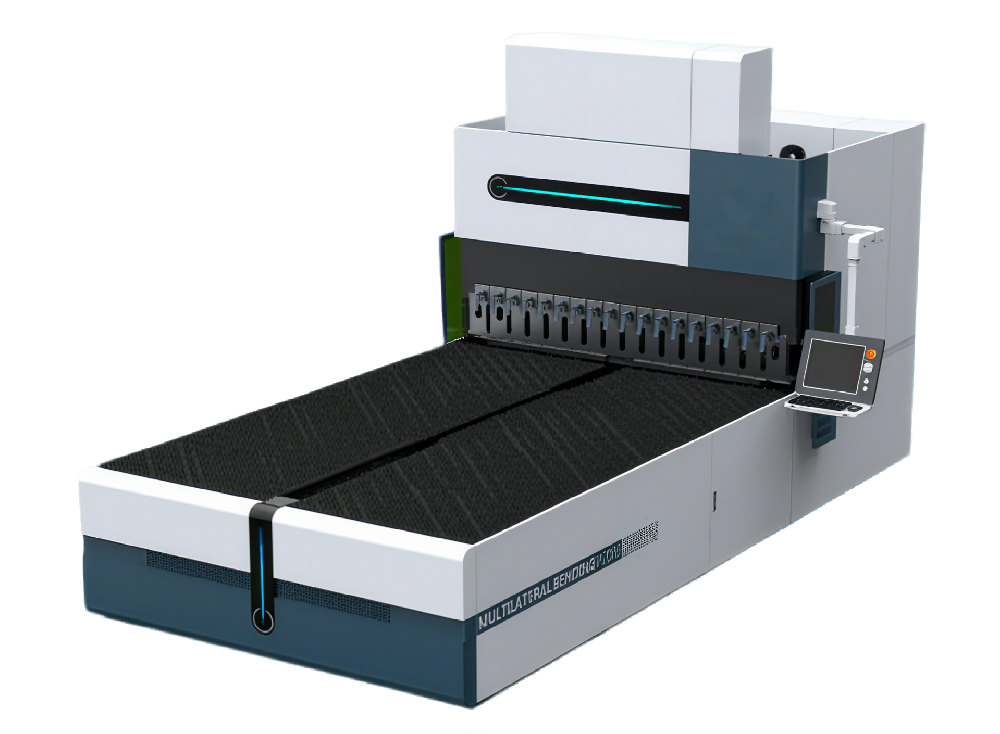

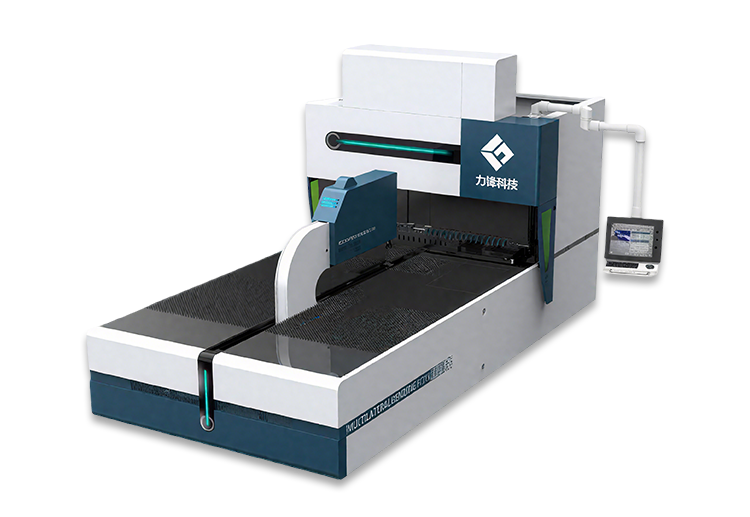

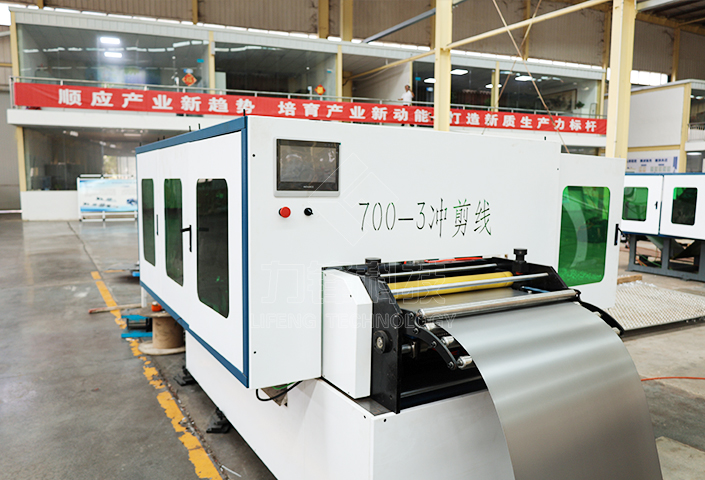

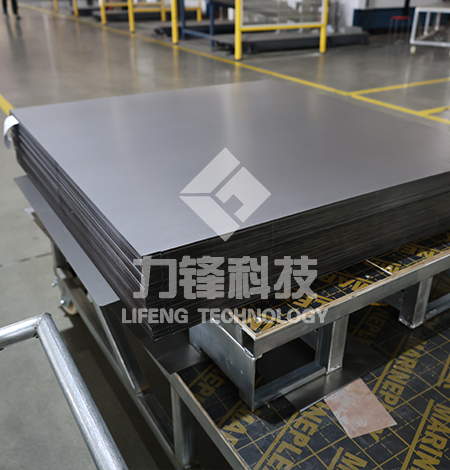

Product show

Product principle

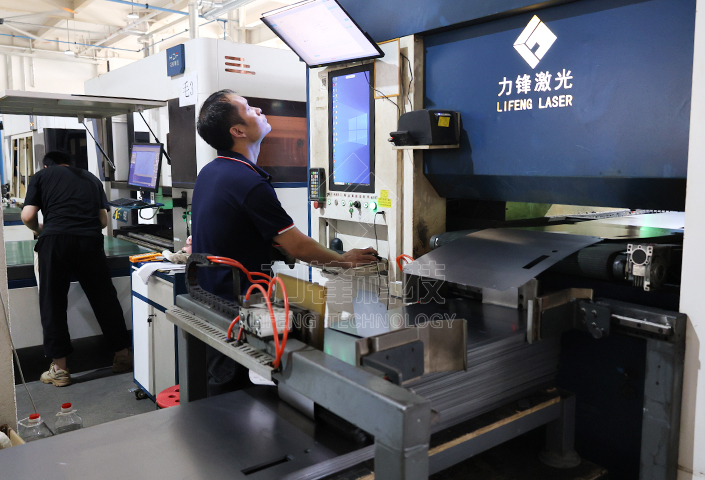

Efficient processing flow — After the CNC system receives parameter instructions, the feeding device accurately conveys sheet metal raw materials to the processing area, and the shearing-punching mechanism quickly completes shearing and punching actions under drive, realizing batch processing.

Flexible parameter adjustment — According to different product processes, the CNC system automatically optimizes parameters like shearing-punching force and tool position, adapting to multi-category processing quickly without manual disassembly and adjustment.

Scenario-based adaptation — In customized configuration, it adapts to complex processing scenarios by adjusting shearing-punching modules and optimizing conveying paths, ensuring stable and efficient operation of the equipment.

Flexible parameter adjustment — According to different product processes, the CNC system automatically optimizes parameters like shearing-punching force and tool position, adapting to multi-category processing quickly without manual disassembly and adjustment.

Scenario-based adaptation — In customized configuration, it adapts to complex processing scenarios by adjusting shearing-punching modules and optimizing conveying paths, ensuring stable and efficient operation of the equipment.

Technical specifications

| Machine Model | LF-CJ-1300 |

| Number of Dies | 6/8 |

| Width Dimension | 1300mm |

| Material Thickness | 0.3-2mm |

| Production Speed | 0-40m/min |

| Product Precision | Trim 0.1mm |

| Uncoiler / Decoiler | Hydraulic Expansion |

| Power Supply Requirement | 380v/50Hz |

| Hydraulic Power | 15kw |

| Hydraulic System Operating Pressure | 15MPa |

Hot sale

CORE EQUIPMENTCUSTOMER CASE

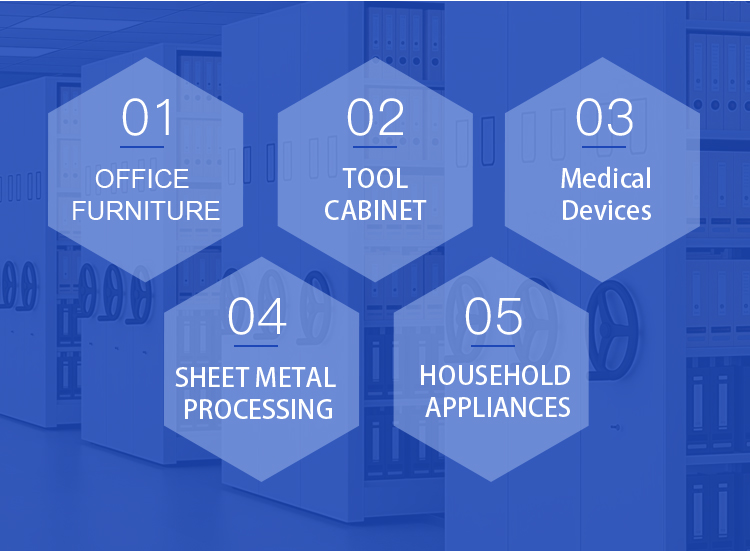

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult