Product advantage

1.Solves the pain point of "slow speed & poor stability" — The Z-axis adopts a patented structure to achieve top operating speed with more stable operation; the all-aluminum flexible welding workbench combined with a small number of high-rigidity intermediate connection structures ensures welding stability.

2.Addresses the problem of "low flexibility & difficult adaptation" — Equipped with dual-rotation displacement interactive workbench with high flexibility; supports multiple welding process options, adapting to welding needs of different sheet metal workpieces and reducing scenario restrictions.

3.Resolves the issue of "insufficient precision & single process" — Weld seam tracking system is optional to improve welding precision; multiple welding process options avoid the situation where complex welding needs cannot be met due to single process.

2.Addresses the problem of "low flexibility & difficult adaptation" — Equipped with dual-rotation displacement interactive workbench with high flexibility; supports multiple welding process options, adapting to welding needs of different sheet metal workpieces and reducing scenario restrictions.

3.Resolves the issue of "insufficient precision & single process" — Weld seam tracking system is optional to improve welding precision; multiple welding process options avoid the situation where complex welding needs cannot be met due to single process.

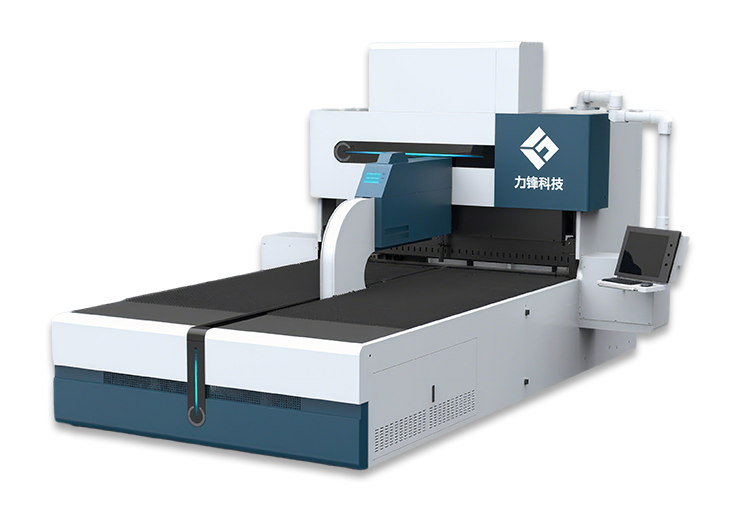

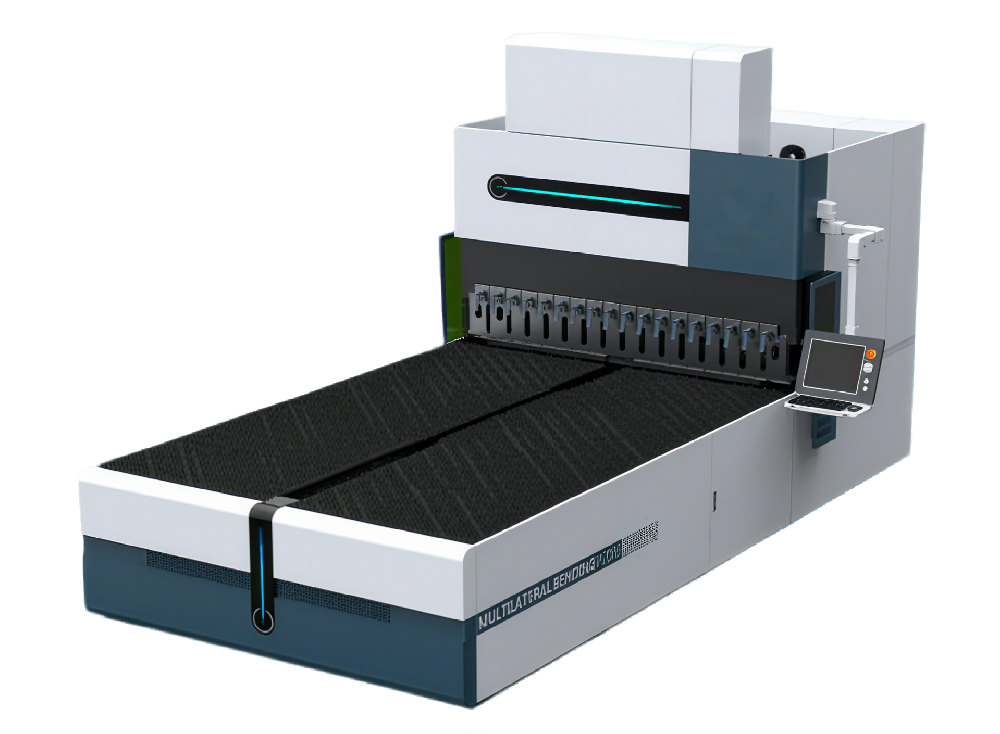

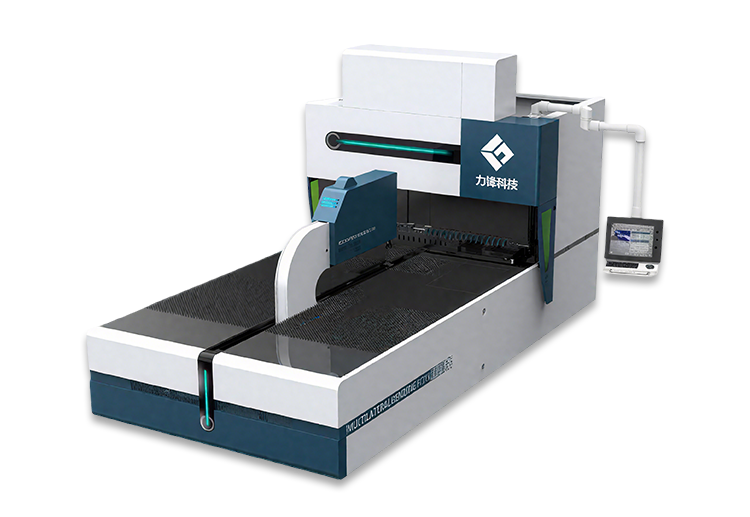

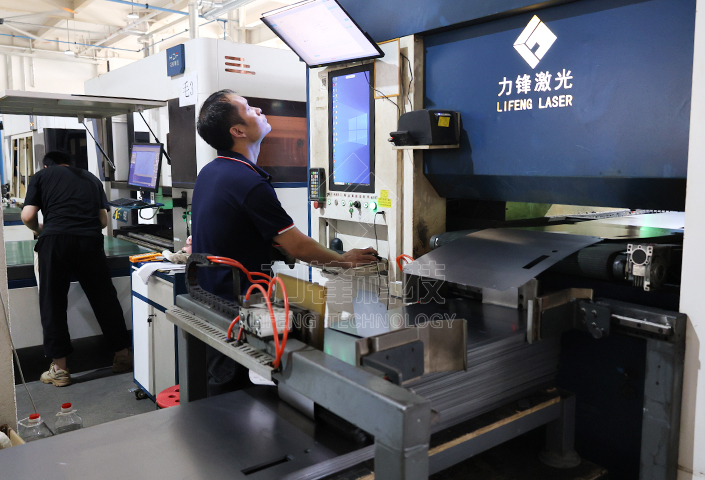

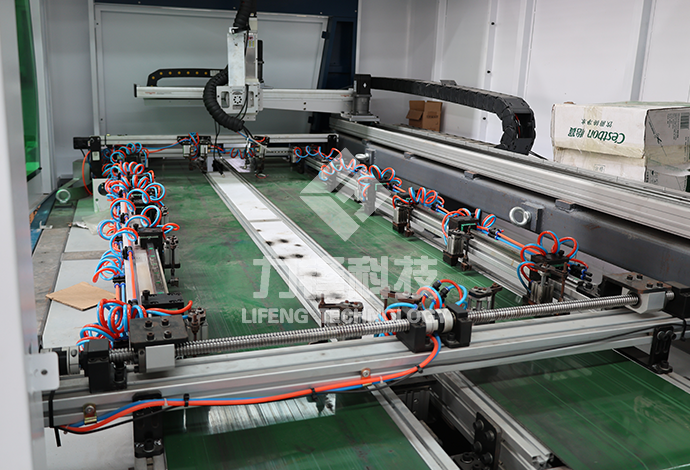

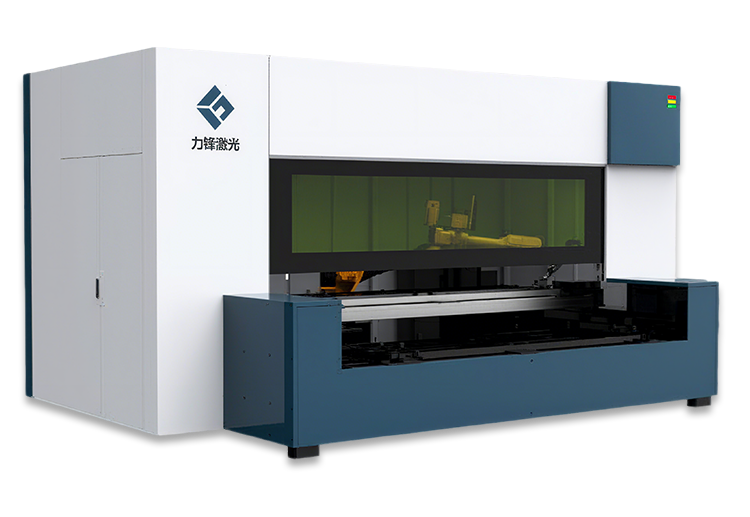

Product show

Product principle

High-speed and stable welding — After the CNC system issues instructions, the patented Z-axis drives the robot welding head to move quickly and accurately; the all-aluminum workbench cooperates with high-rigidity connection structures to ensure welding stability during high-speed operation, improving efficiency and precision.

Flexible adaptation to welding — The dual-rotation displacement workbench can adjust the angle and position of workpieces, and cooperate with the switching of multiple welding processes, without frequent tooling replacement, quickly adapting to welding needs of different workpieces.

Precise and intelligent control — The optional weld seam tracking system monitors the welding trajectory in real time and corrects deviations; dual PCs and interactive interface realize process parameter setting and welding monitoring, ensuring welding precision and intelligent operation.

Flexible adaptation to welding — The dual-rotation displacement workbench can adjust the angle and position of workpieces, and cooperate with the switching of multiple welding processes, without frequent tooling replacement, quickly adapting to welding needs of different workpieces.

Precise and intelligent control — The optional weld seam tracking system monitors the welding trajectory in real time and corrects deviations; dual PCs and interactive interface realize process parameter setting and welding monitoring, ensuring welding precision and intelligent operation.

Technical specifications

| Machine Model | LF-ETM-2612 |

| Maximum Welding Area | 2600x1200mm |

| Material Thickness Range | Wire Feeding: 0.8-5mm; Non-Wire Feeding: 0.4-5mm |

| Welding Height Range | <500mm |

| Robot Arm Length | 2000-2100mm |

| Positioning Accuracy | 去0.05mm |

| Welding Method | Laser Welding |

| Gas Used / Operating Gas | Air / Argon |

| Air Pressure Requirement | 1.2MPa |

| Weldable Materials | Carbon Steel, Stainless Steel, Aluminum Plate |

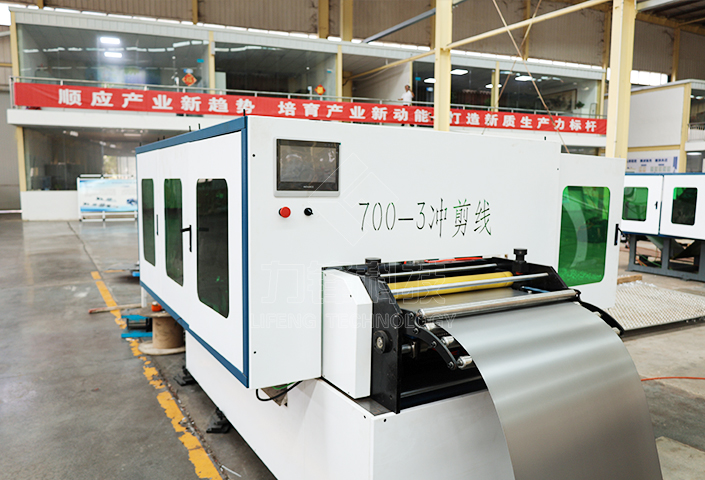

Hot sale

CORE EQUIPMENTCUSTOMER CASE

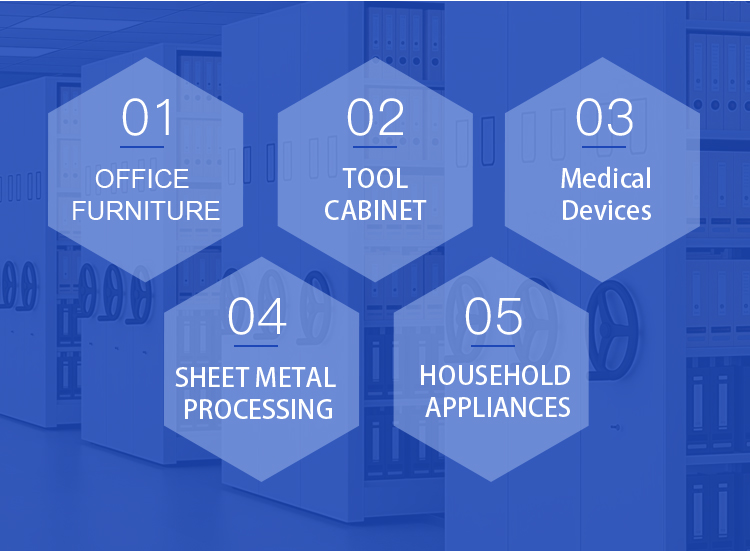

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult