Product advantage

1.Solves the pain point of "low precision & high cost" — Assembled with imported key components and advanced technology, it has high cutting precision and speed, effectively saving processing materials and reducing processing costs; lasers, cutting heads and other key components from well-known domestic and international brands ensure stable performance.

2.Addresses the problem of "few adaptations & narrow scenarios" — It can cut all metal materials such as stainless steel, carbon steel, aluminum, brass and red copper, adapting to multi-category sheet metal processing without frequent equipment replacement, expanding application scenarios.

3.Resolves the issue of "poor stability & complicated maintenance" — Gantry structure + high-strength, high-rigidity aviation aluminum cast beam ensures strong equipment stability; maintenance-free optical path design reduces later maintenance costs and workload.

2.Addresses the problem of "few adaptations & narrow scenarios" — It can cut all metal materials such as stainless steel, carbon steel, aluminum, brass and red copper, adapting to multi-category sheet metal processing without frequent equipment replacement, expanding application scenarios.

3.Resolves the issue of "poor stability & complicated maintenance" — Gantry structure + high-strength, high-rigidity aviation aluminum cast beam ensures strong equipment stability; maintenance-free optical path design reduces later maintenance costs and workload.

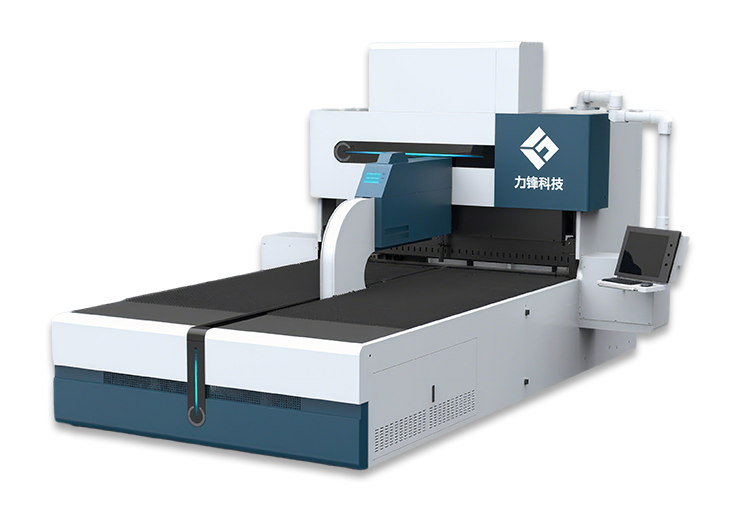

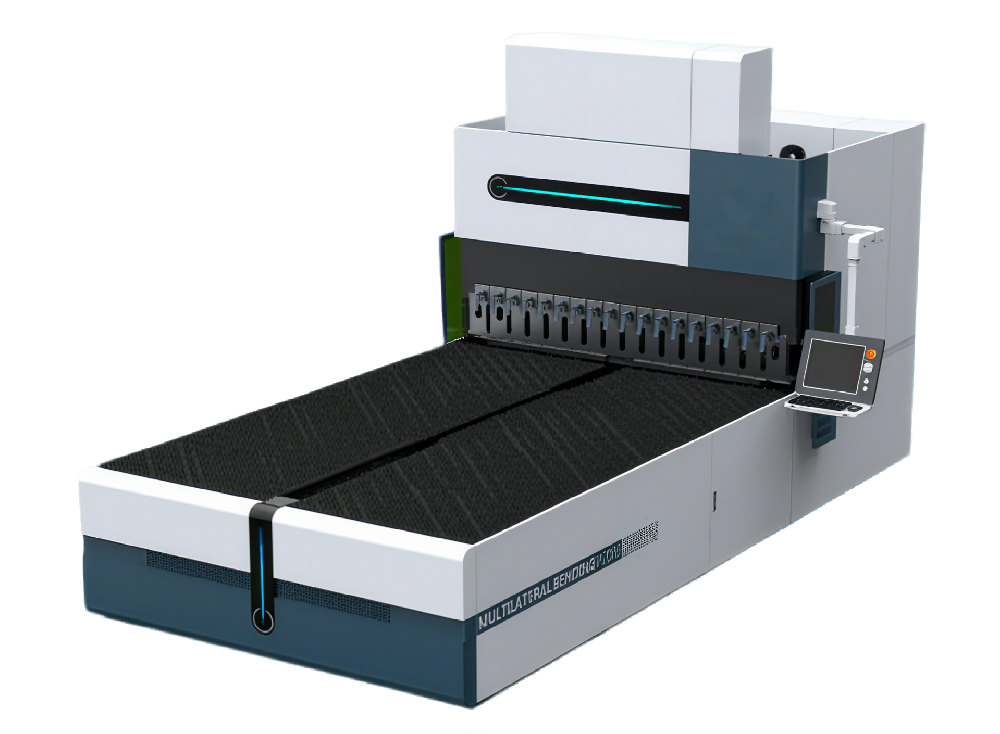

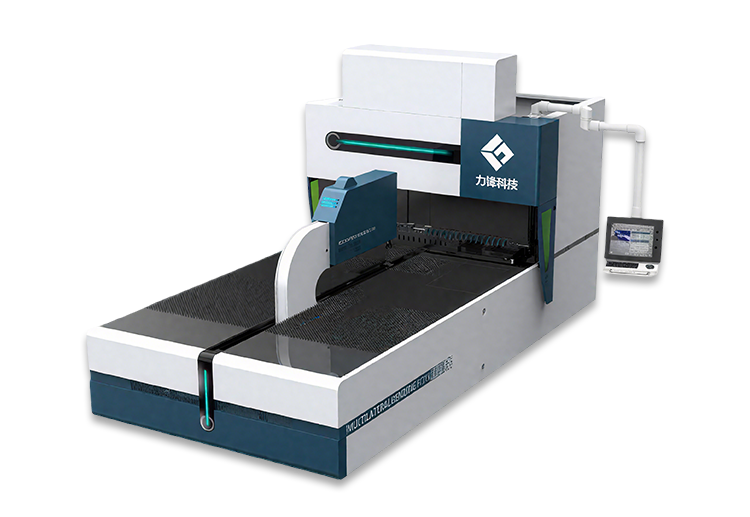

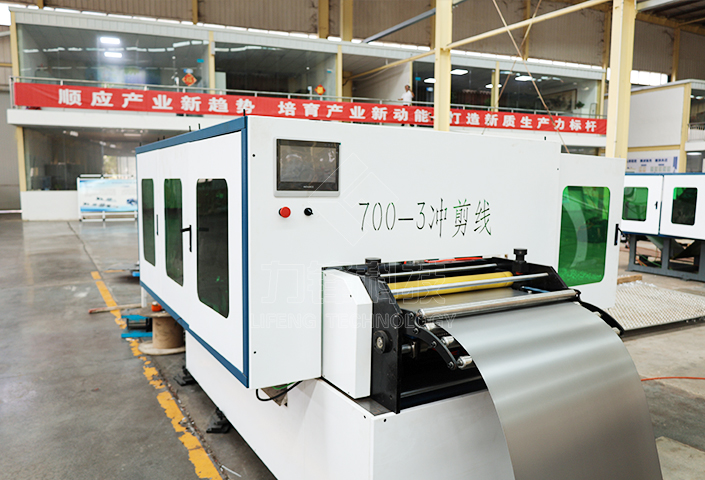

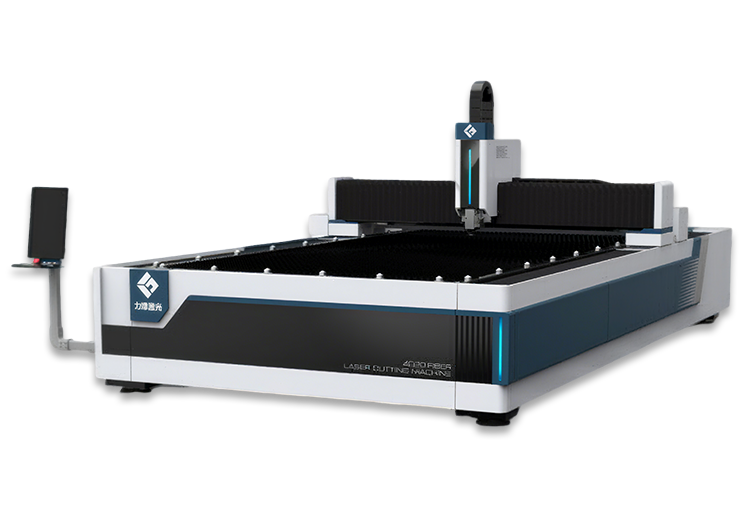

Product show

Product principle

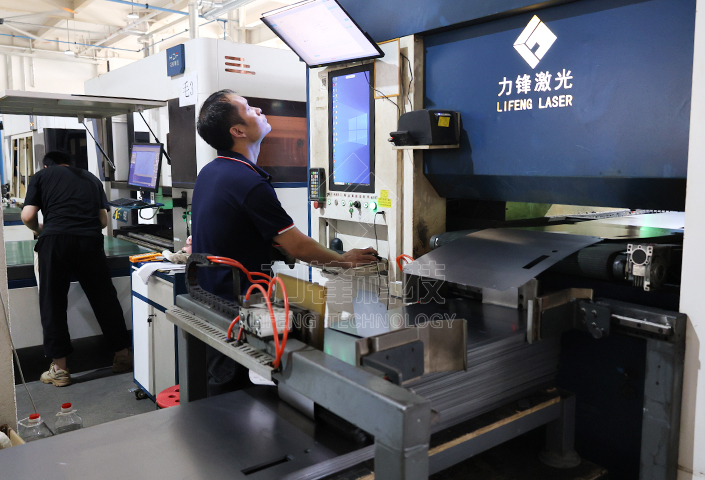

Core of high-precision cutting — After the CNC system issues instructions, the laser from a well-known brand emits laser light, which is focused on the metal sheet surface through the cutting head; imported transmission components (reducers, gear racks) drive the workbench to move accurately, realizing high-precision and high-speed cutting and reducing material waste.

All-metal adaptive cutting — According to the characteristics of different metal materials (such as stainless steel, aluminum), the CNC system automatically adjusts parameters such as laser power and cutting speed, and can adapt to multiple metal cutting needs without replacing core components.

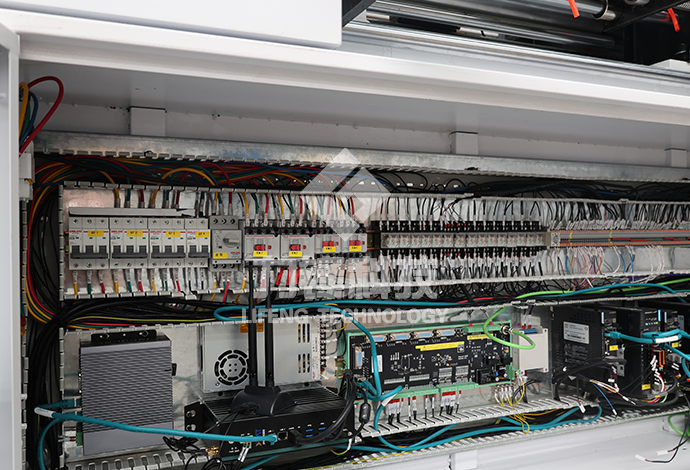

Stable and low-maintenance operation — The gantry structure and aviation aluminum beam ensure the stability of the equipment during operation, avoiding vibration affecting cutting precision; the maintenance-free optical path design reduces regular inspection and repair links, lowers maintenance costs and ensures long-term efficient operation.

All-metal adaptive cutting — According to the characteristics of different metal materials (such as stainless steel, aluminum), the CNC system automatically adjusts parameters such as laser power and cutting speed, and can adapt to multiple metal cutting needs without replacing core components.

Stable and low-maintenance operation — The gantry structure and aviation aluminum beam ensure the stability of the equipment during operation, avoiding vibration affecting cutting precision; the maintenance-free optical path design reduces regular inspection and repair links, lowers maintenance costs and ensures long-term efficient operation.

Technical specifications

| Machine Model | LF-P-AE-4515 | LF-P-AE-6025 | LF-P-AE-8025 |

| Cutting Area | 4500x1500mm | 6000x2500mm | 8000x2500mm |

| X-Axis Stroke | 1500mm | 2500mm | |

| Y-Axis Stroke | 4500mm | 6000mm | 8000mm |

| Z-Axis Stroke | 250mm | ||

| Minimum Cutting Edge | 1mm | ||

| Positioning Accuracy | 去0.3mm | ||

| Maximum Positioning Speed | 120m/min | ||

| Maximum Acceleration | 1.5G | ||

| Gas Used / Operating Gas | Air / Oxygen / Nitrogen | ||

Hot sale

CORE EQUIPMENTCUSTOMER CASE

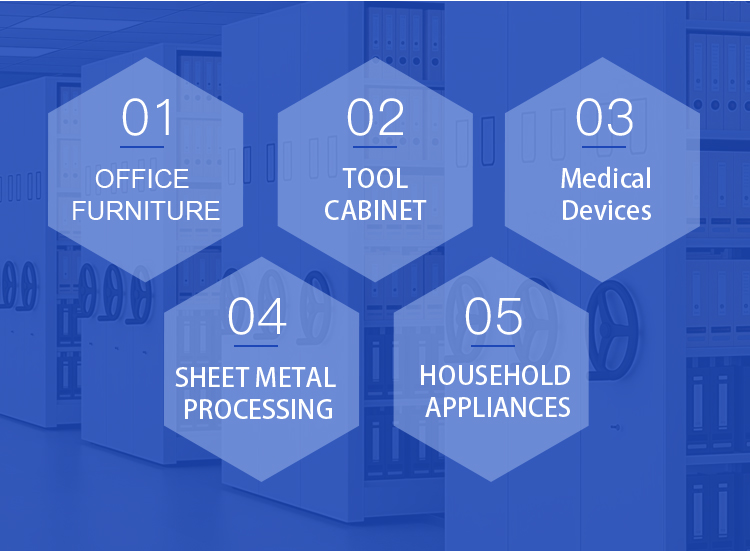

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult