Product advantage

1.Solves the pain point of "high failure rate & expensive maintenance" — Adopts advanced technology, with low failure rate, greatly reducing maintenance costs, minimizing equipment downtime losses and ensuring continuous production.

2.Addresses the problem of "poor precision & difficult management" — Advanced control system + sensors realize high-precision welding; can record welding data, facilitating production management and process analysis, and improving quality control capabilities.

3.Resolves the issue of "difficult operation & slow learning" — Easy to operate, new employees can get started without training after program editing; avoids complex operation thresholds and reduces enterprises' personnel training costs.

4.Overcomes the difficulty of "low efficiency & insufficient capacity" — Supports programming to set different welding modes and parameters, adapting to diverse needs; skilled personnel can process 1000-1500 door panels per day, greatly improving batch production efficiency.

2.Addresses the problem of "poor precision & difficult management" — Advanced control system + sensors realize high-precision welding; can record welding data, facilitating production management and process analysis, and improving quality control capabilities.

3.Resolves the issue of "difficult operation & slow learning" — Easy to operate, new employees can get started without training after program editing; avoids complex operation thresholds and reduces enterprises' personnel training costs.

4.Overcomes the difficulty of "low efficiency & insufficient capacity" — Supports programming to set different welding modes and parameters, adapting to diverse needs; skilled personnel can process 1000-1500 door panels per day, greatly improving batch production efficiency.

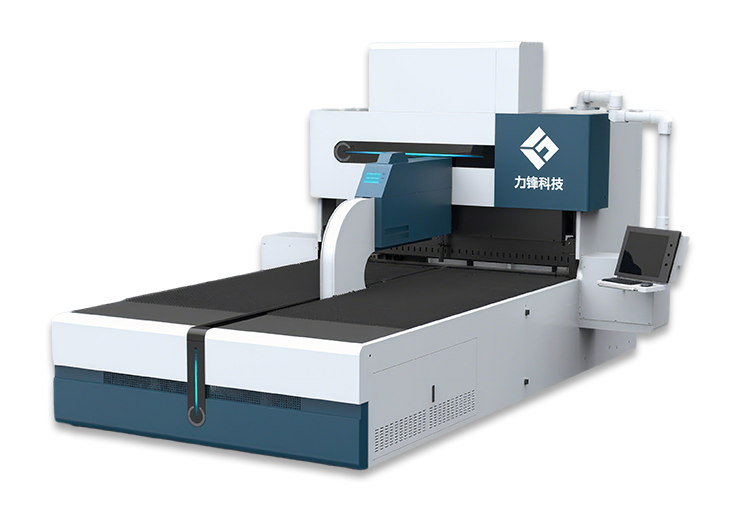

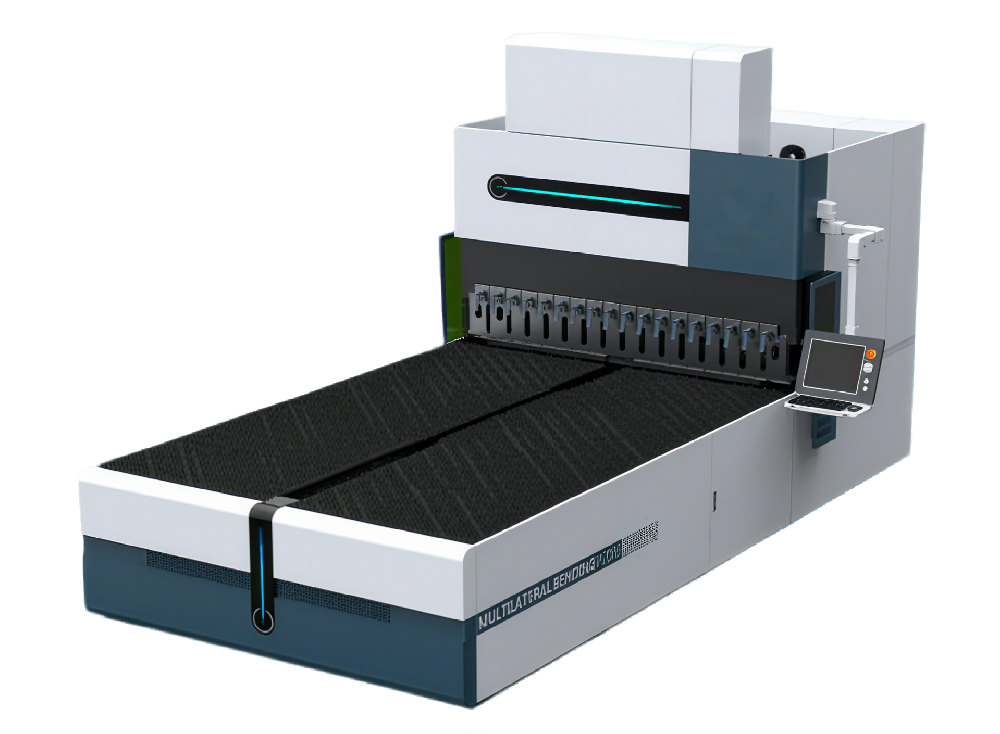

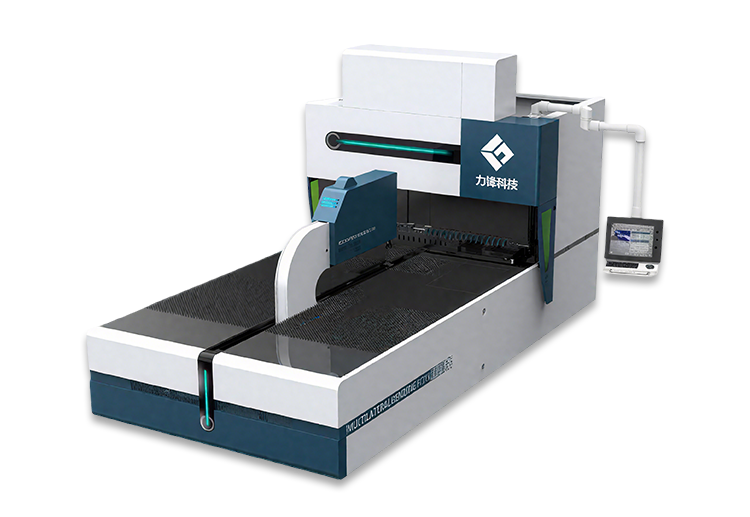

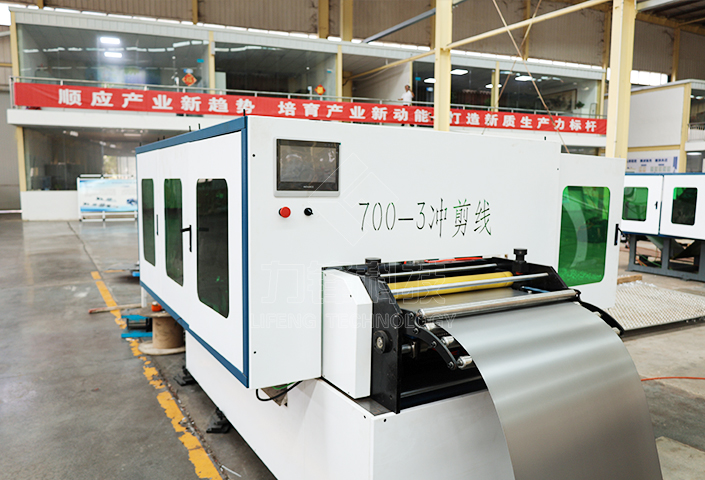

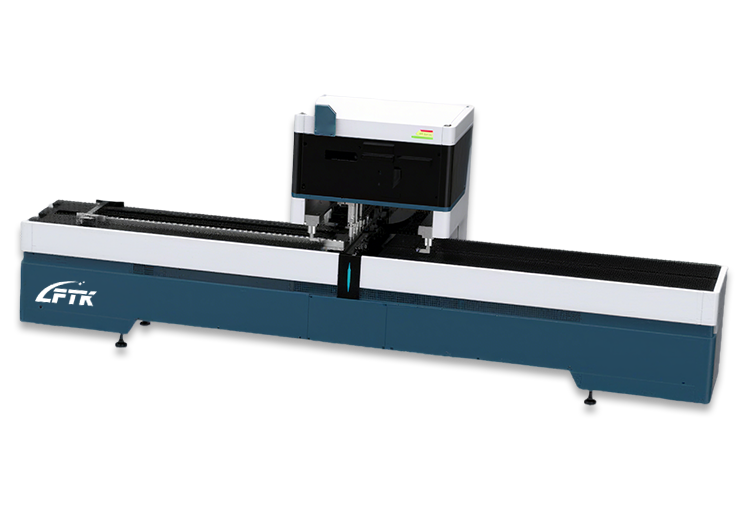

Product show

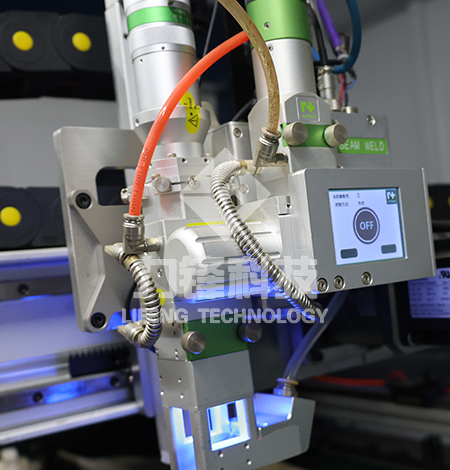

Product principle

Precise welding control — After the advanced control system receives programming parameters, it drives sensors to monitor the welding position and status in real time, adjusts welding energy and rhythm, ensures high-precision welding and reduces workpiece errors.

Intelligent data management — During welding, the equipment automatically records data such as welding parameters and time, stores them in the system for subsequent retrieval and analysis, facilitating production process optimization and quality traceability.

Efficient batch operation — After the operator edits the welding program, the equipment automatically completes welding according to the preset mode; no complex manual intervention is required, new employees can get started quickly, and combined with parameter adaptability, it realizes high single-person capacity (1000-1500 door panels processed per day) for batch production.

Intelligent data management — During welding, the equipment automatically records data such as welding parameters and time, stores them in the system for subsequent retrieval and analysis, facilitating production process optimization and quality traceability.

Efficient batch operation — After the operator edits the welding program, the equipment automatically completes welding according to the preset mode; no complex manual intervention is required, new employees can get started quickly, and combined with parameter adaptability, it realizes high single-person capacity (1000-1500 door panels processed per day) for batch production.

Technical specifications

| Machine Model | 1370 | 2070 |

| Minimum Welding Area | 200x200mm | |

| Maximum Welding Area | 1300x700mm | 2000x700mm |

| Maximum Material Thickness | s1.0mm | |

| Power | 25kw | |

| Voltage | 380V | |

| Welding Mode | Spot Welding, Continuous Welding | |

| Welding Color | Blue-White | |

| Cooling Water Consumption | 250L/H | |

| Maximum Welding Speed | 90 Times/Minute | |

| Control | CNC PLC | |

Hot sale

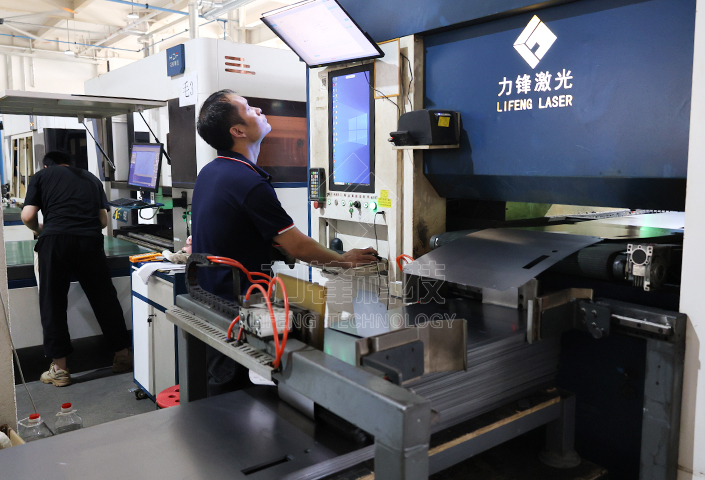

CORE EQUIPMENTCUSTOMER CASE

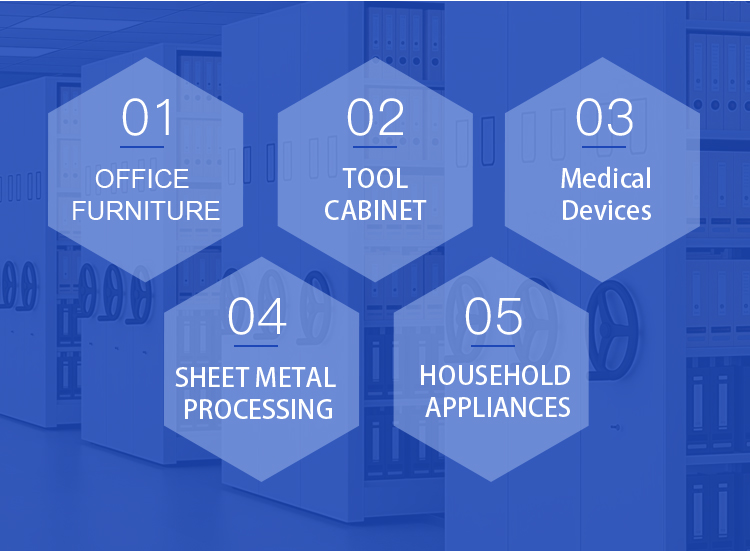

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult