Product advantage

1.Solves the pain point of "slow speed & poor stability" — The Z-axis adopts a patented structure, with faster and more stable operation; the high-strength integral cast aluminum alloy beam is suitable for high-speed operation, improving welding efficiency and quality stability.

2.Addresses the problem of "difficult adaptation & great limitations" — The alloy welding table has small welding limitations, and a small number of high-rigidity intermediate connection structures adapt to various sheet metal workpieces, reducing scenario restrictions.

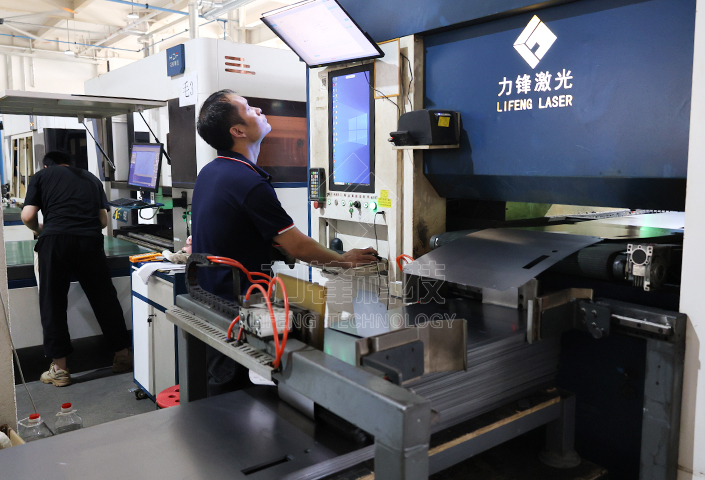

3.Resolves the issue of "complicated operation & low intelligence" — Equipped with dual PC configuration and large screen for easy operation; supports cloud service function to realize intelligent management, reducing the complexity of manual operation.

2.Addresses the problem of "difficult adaptation & great limitations" — The alloy welding table has small welding limitations, and a small number of high-rigidity intermediate connection structures adapt to various sheet metal workpieces, reducing scenario restrictions.

3.Resolves the issue of "complicated operation & low intelligence" — Equipped with dual PC configuration and large screen for easy operation; supports cloud service function to realize intelligent management, reducing the complexity of manual operation.

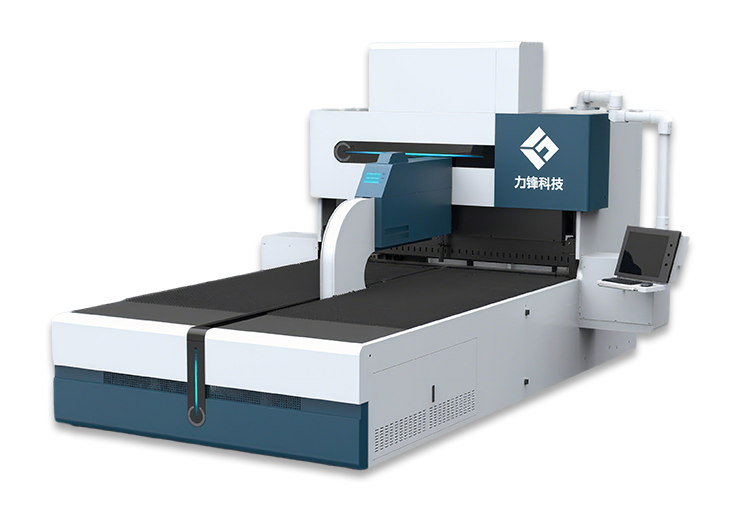

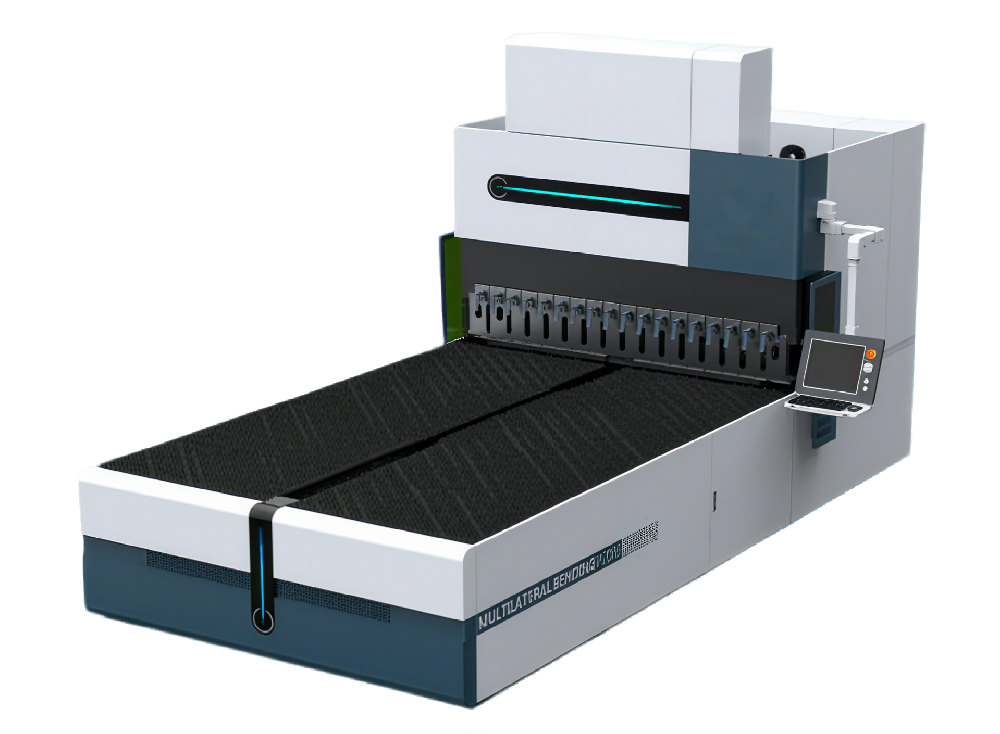

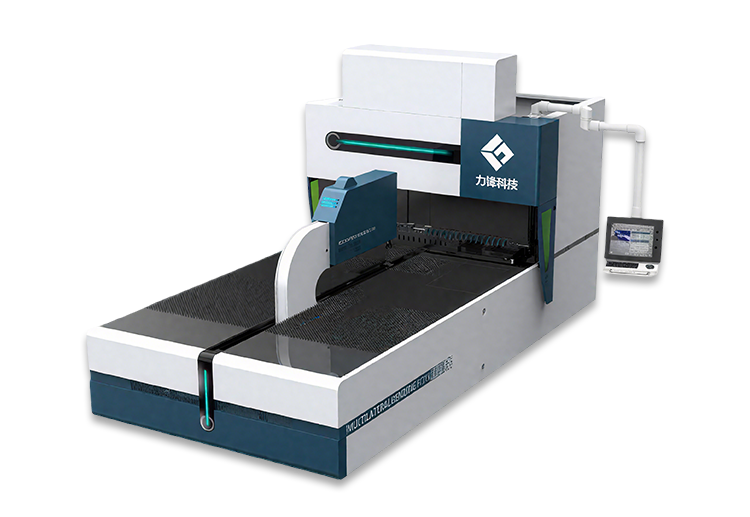

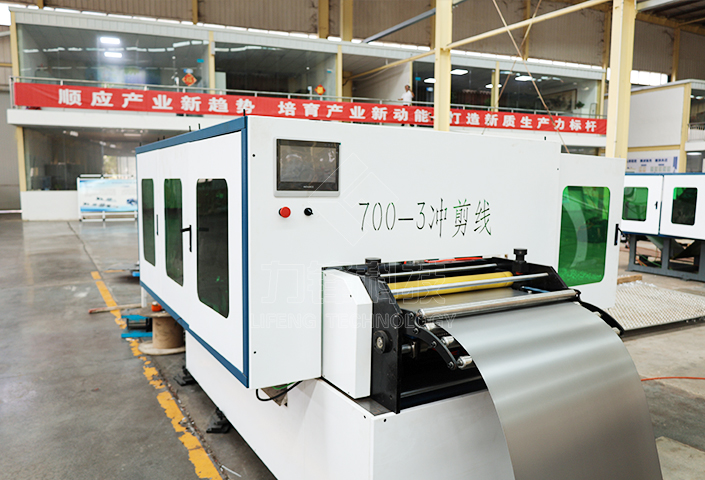

Product show

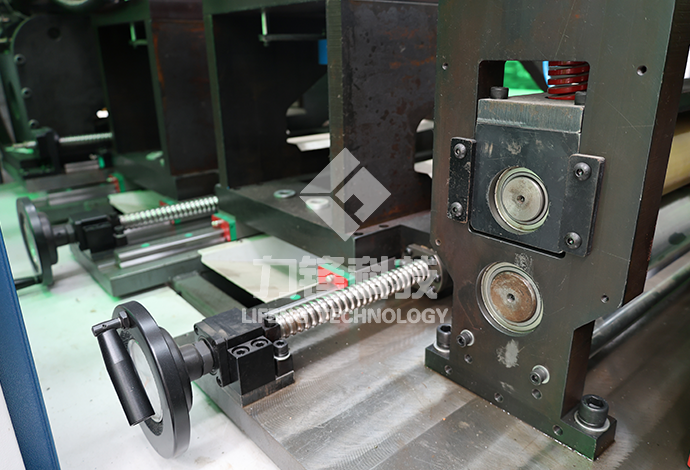

Product principle

High-speed and stable welding — After the CNC system issues instructions, the patented Z-axis structure drives the welding head to move quickly and accurately; the aluminum alloy beam ensures stability during high-speed operation, and the laser device completes welding according to the preset path, improving efficiency and precision.

Flexible adaptation to processing — The alloy welding table and high-rigidity connection structure cooperate to adapt to sheet metal workpieces of different sizes and shapes, without frequent tooling replacement, meeting diverse welding needs.

Intelligent operation and management — Dual PC and large screen enable convenient parameter setting and welding monitoring; the cloud service function synchronizes data in real time, supporting remote management and data analysis, improving operation convenience and intelligence level.

Flexible adaptation to processing — The alloy welding table and high-rigidity connection structure cooperate to adapt to sheet metal workpieces of different sizes and shapes, without frequent tooling replacement, meeting diverse welding needs.

Intelligent operation and management — Dual PC and large screen enable convenient parameter setting and welding monitoring; the cloud service function synchronizes data in real time, supporting remote management and data analysis, improving operation convenience and intelligence level.

Technical specifications

| Machine Model | LF-E-b-2111 |

| Maximum Welding Area | 2100x900mm |

| X-Axis Stroke | 2100mm |

| Y-Axis Stroke | 900mm |

| Z-Axis Stroke | 400mm |

| Maximum Welding Height | 60mm |

| Maximum Material Thickness | 4mm |

| Positioning Accuracy | ≤±0.05mm |

| Maximum Positioning Speed | 120m/min |

| Maximum Acceleration | 1.5G |

| Gas Used | Air / Argon |

Hot sale

CORE EQUIPMENTCUSTOMER CASE

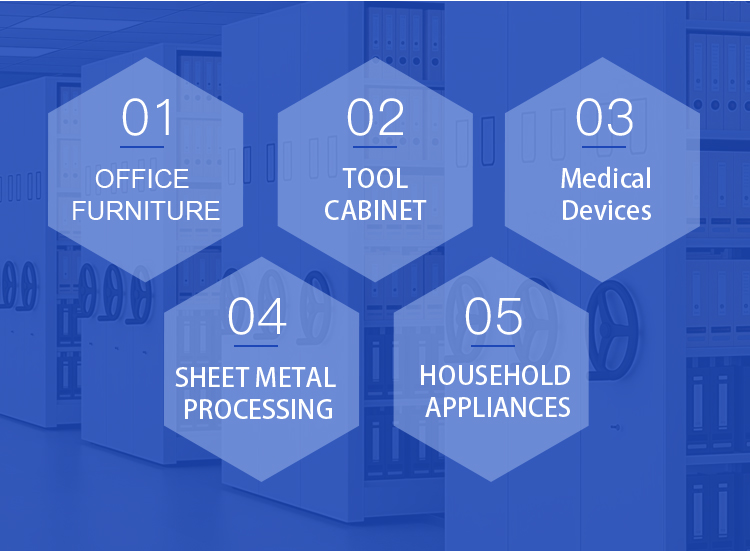

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult