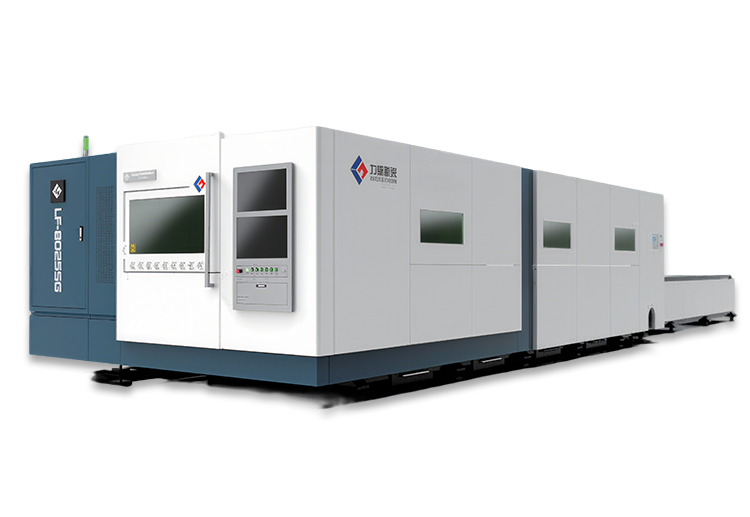

Product advantage

1.Solves the pain point of "low efficiency & difficult heavy-duty processing" — Top operating speed improves cutting efficiency; the rear translation structure suitable for heavy loads adapts to heavy workpiece processing, avoiding equipment jamming under heavy loads.

2.Addresses the problem of "much dust & poor environment" — Two-way positive pressure dust removal system efficiently collects cutting dust; the protected hollow bed reduces dust accumulation, improves processing environment and lowers dust damage to equipment.

3.Resolves the issue of "angle limitation & complicated operation" — 360° free rotating cutting structure (max. ±45° cutting angle) adapts to complex angle cutting; full bus system + dual-screen design balances monitoring and operation, simplifying the operation process.

4.Overcomes the difficulty of "slow blanking & high labor intensity" — The blanking conveying module in the feeding area automatically conveys finished products, reducing manual handling, lowering workers' labor intensity and improving overall production efficiency.

2.Addresses the problem of "much dust & poor environment" — Two-way positive pressure dust removal system efficiently collects cutting dust; the protected hollow bed reduces dust accumulation, improves processing environment and lowers dust damage to equipment.

3.Resolves the issue of "angle limitation & complicated operation" — 360° free rotating cutting structure (max. ±45° cutting angle) adapts to complex angle cutting; full bus system + dual-screen design balances monitoring and operation, simplifying the operation process.

4.Overcomes the difficulty of "slow blanking & high labor intensity" — The blanking conveying module in the feeding area automatically conveys finished products, reducing manual handling, lowering workers' labor intensity and improving overall production efficiency.

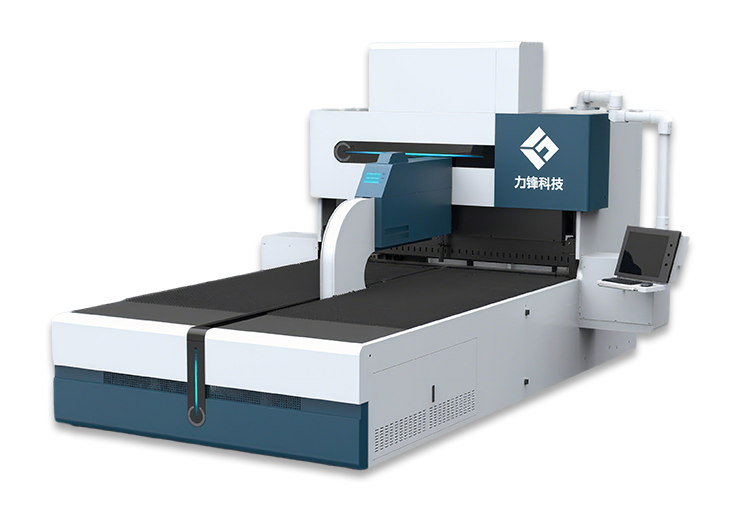

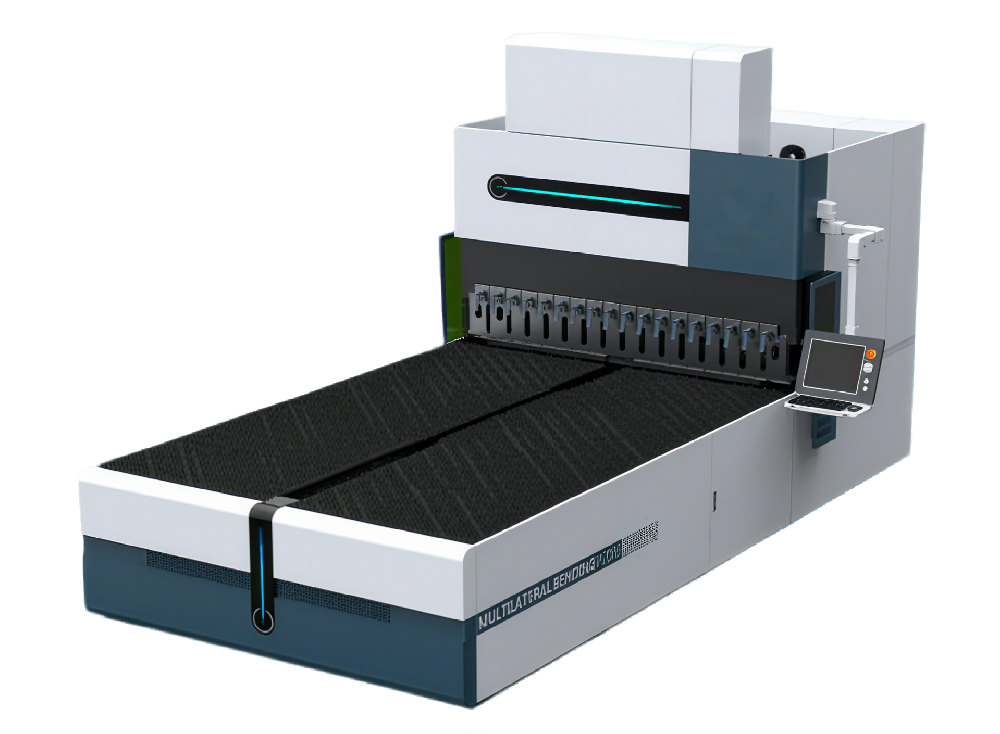

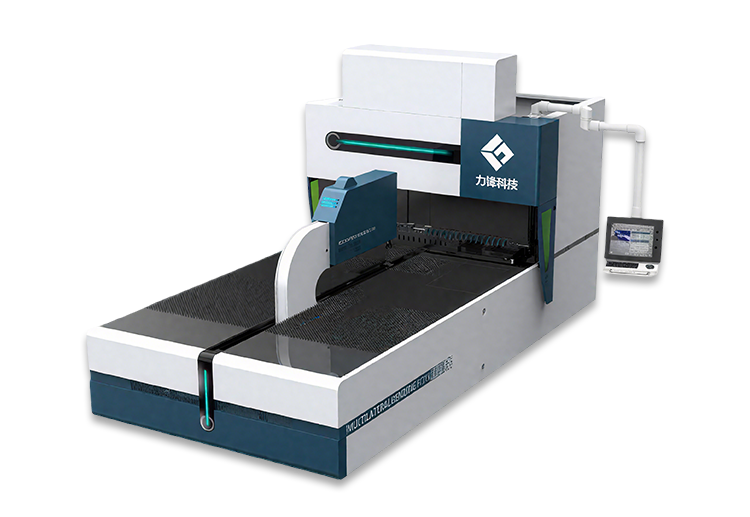

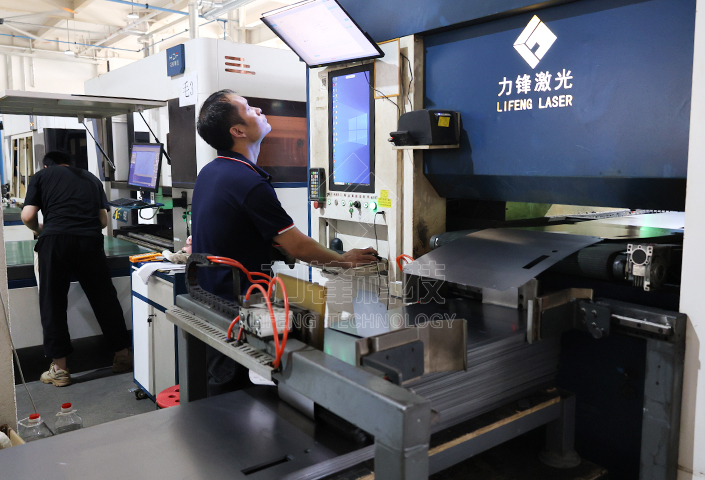

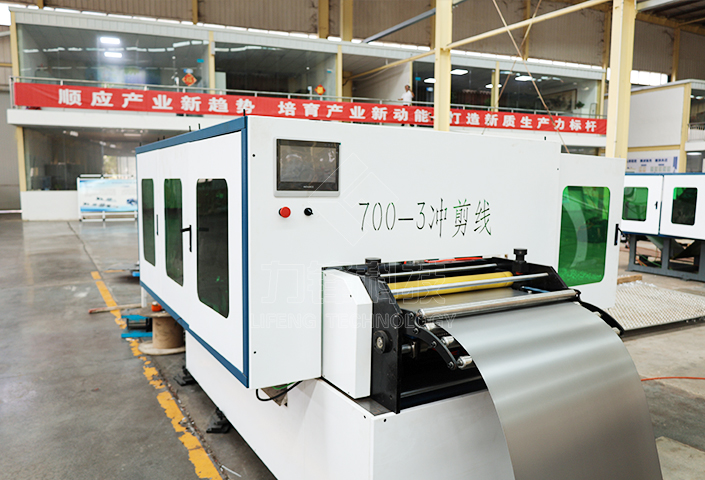

Product show

Product principle

High-speed heavy-duty cutting — After the CNC system issues instructions, the equipment drives the cutting head to run at top speed; the rear translation structure stably bears heavy workpieces, and the 360° rotating cutting structure adjusts the angle (within ±45°) as needed to accurately complete complex angle cutting.

Clean dust removal guarantee — The two-way positive pressure dust removal system generates positive pressure airflow in real time during cutting, sucking dust into the collection channel inside the hollow bed, avoiding dust diffusion and keeping the processing environment clean and equipment parts clean.

Intelligent and convenient operation — Dual screens realize processing monitoring and parameter operation respectively; the full bus system ensures the coordinated operation of all components; after cutting, the blanking conveying module in the feeding area automatically conveys finished products to the designated area, forming an efficient "feeding-cutting-blanking" process.

Clean dust removal guarantee — The two-way positive pressure dust removal system generates positive pressure airflow in real time during cutting, sucking dust into the collection channel inside the hollow bed, avoiding dust diffusion and keeping the processing environment clean and equipment parts clean.

Intelligent and convenient operation — Dual screens realize processing monitoring and parameter operation respectively; the full bus system ensures the coordinated operation of all components; after cutting, the blanking conveying module in the feeding area automatically conveys finished products to the designated area, forming an efficient "feeding-cutting-blanking" process.

Technical specifications

| Machine Model | LF-JY-6025 | LF-JFY-8025 | LF-JFY-8025 | |||

| Cutting Area | 6000x2500mm | 8000x2500mm | 8000x2500mm | |||

| X-Axis Stroke | 2500mm | |||||

| Y-Axis Stroke | 6000mm | 8000mm | 10000mm | |||

| Z-Axis Stroke | 250 | |||||

| Minimum Cutting Edge | 1mm | |||||

| Worktable Load Capacity | 6000KG | 8000KG | ||||

| Maximum Positioning Speed | 120m/min | |||||

| Maximum Acceleration | 1.5G | |||||

| Gas Used / Operating Gas | Air / Oxygen / Nitrogen | |||||

Hot sale

CORE EQUIPMENTCUSTOMER CASE

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult