Product advantage

1.Solves the pain point of "low efficiency and long cycle" — Adopts advanced shearing and punching technology to complete a large number of production tasks in a short time, greatly improving production efficiency and significantly shortening the production cycle, far exceeding traditional manual processing.

2.Addresses the problem of "poor flexibility and difficult adaptation" — Has high flexibility to meet the production needs of different products, no need for frequent equipment adjustment, and adapts to multi-category sheet metal processing scenarios.

3.Resolves the issue of "single scenario and difficult customization" — Can be customized according to enterprises' production needs, able to adapt to various complex and changeable processing scenarios, avoiding the situation that equipment cannot be used due to scenario limitations.

2.Addresses the problem of "poor flexibility and difficult adaptation" — Has high flexibility to meet the production needs of different products, no need for frequent equipment adjustment, and adapts to multi-category sheet metal processing scenarios.

3.Resolves the issue of "single scenario and difficult customization" — Can be customized according to enterprises' production needs, able to adapt to various complex and changeable processing scenarios, avoiding the situation that equipment cannot be used due to scenario limitations.

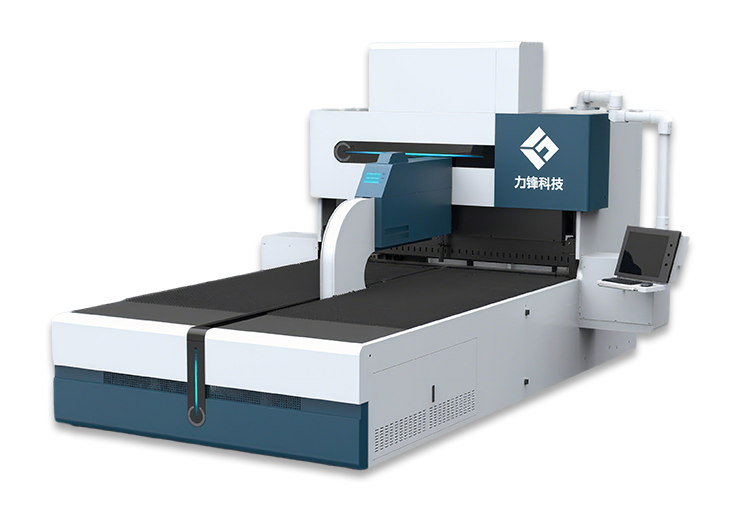

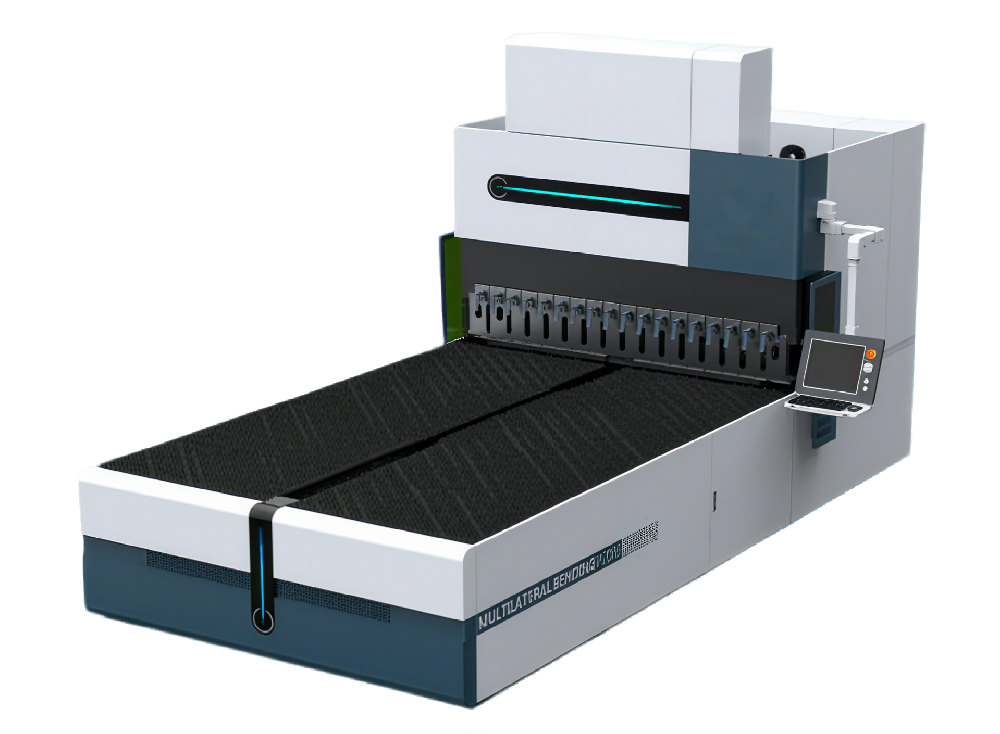

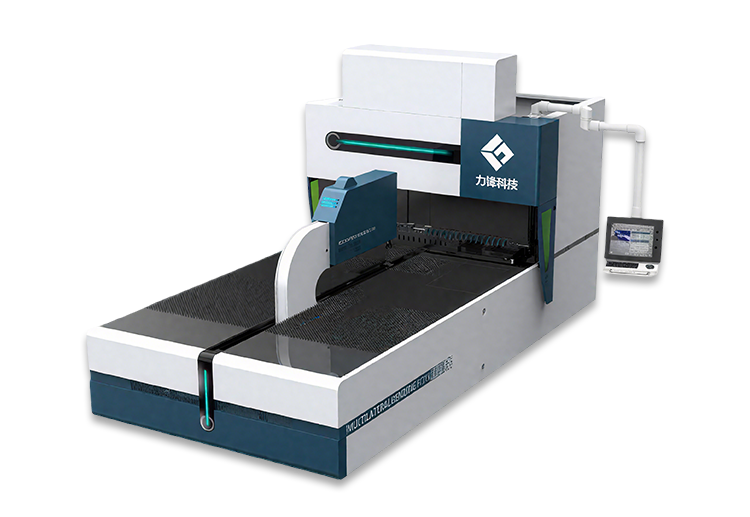

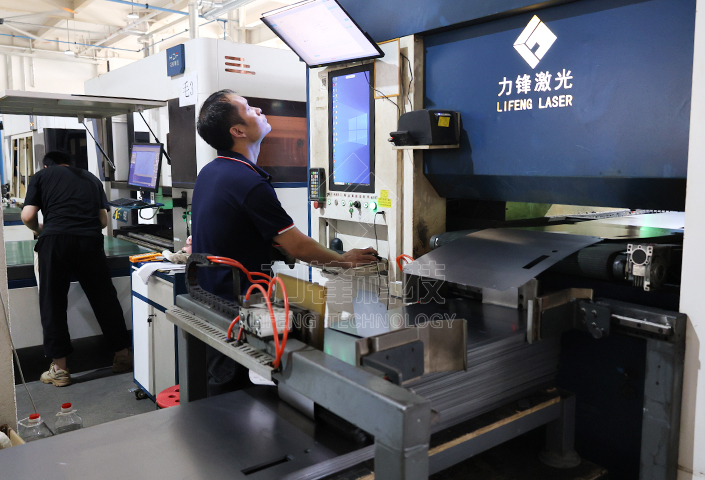

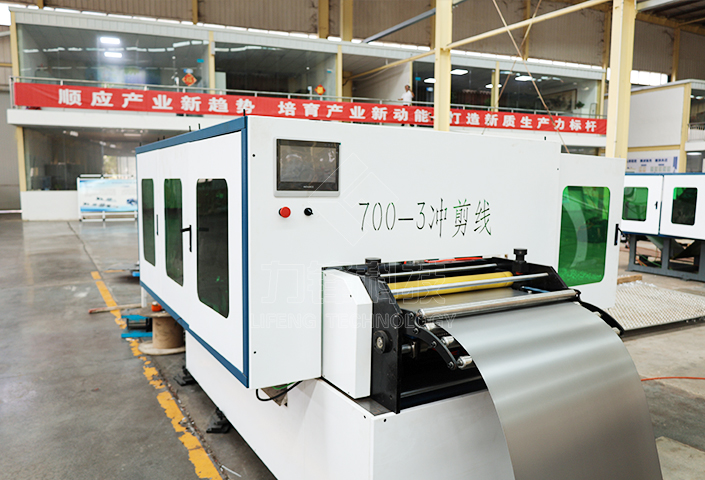

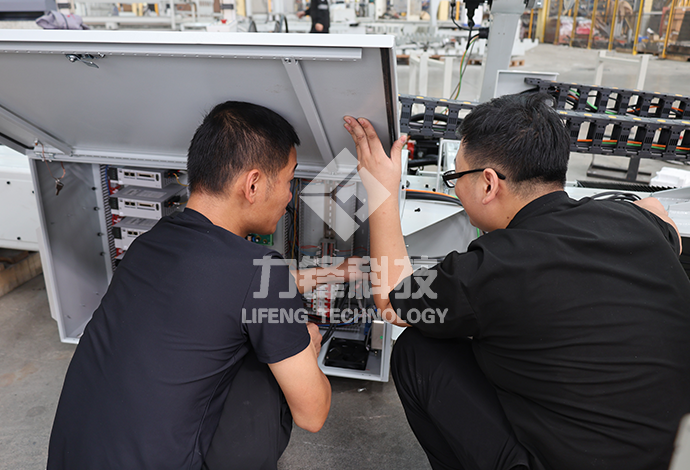

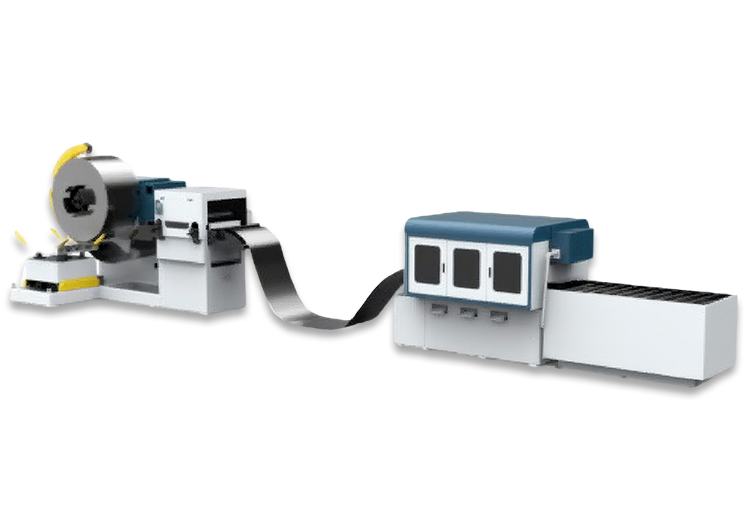

Product show

Product principle

Core of efficient shearing and punching — Relying on advanced shearing and punching technology, after the equipment receives CNC instructions, the shearing and punching mechanism acts on the sheet metal material accurately, quickly completing processing actions such as shearing and punching to achieve batch efficient processing.

Flexible adaptation control — The CNC system automatically adjusts shearing and punching parameters (such as force, position, times) according to the processing needs of different products, no need for frequent manual debugging, to meet diversified product processing needs.

Customized scenario adaptation — According to enterprises' customization needs, optimize the equipment structure (such as shearing and punching modules, conveying paths) to enable the equipment to adapt to complex and changeable processing scenarios and ensure stable and efficient operation under different production needs.

Flexible adaptation control — The CNC system automatically adjusts shearing and punching parameters (such as force, position, times) according to the processing needs of different products, no need for frequent manual debugging, to meet diversified product processing needs.

Customized scenario adaptation — According to enterprises' customization needs, optimize the equipment structure (such as shearing and punching modules, conveying paths) to enable the equipment to adapt to complex and changeable processing scenarios and ensure stable and efficient operation under different production needs.

Technical specifications

| Machine Model | LF-CJ-700 | LF-CJ-1000 |

| Number of Dies | 416 | 41618 |

| Width Dimension | 700mm | 1000mm |

| Material Thickness | 0.3-2mm | 0.3-2mm |

| Production Speed | 0-40m/min | 0-40m/min |

| Product Precision | Remove 0.1mm | Remove 0.1mm |

| Uncoiler | Hydraulic Expansion | Hydraulic Expansion |

| Power Supply Requirement | 380v/50Hz | 380v/50Hz |

| Hydraulic Power | 15kw | 15kw |

| Hydraulic System Operating Pressure | 15MPa | 15MPa |

Hot sale

CORE EQUIPMENTCUSTOMER CASE

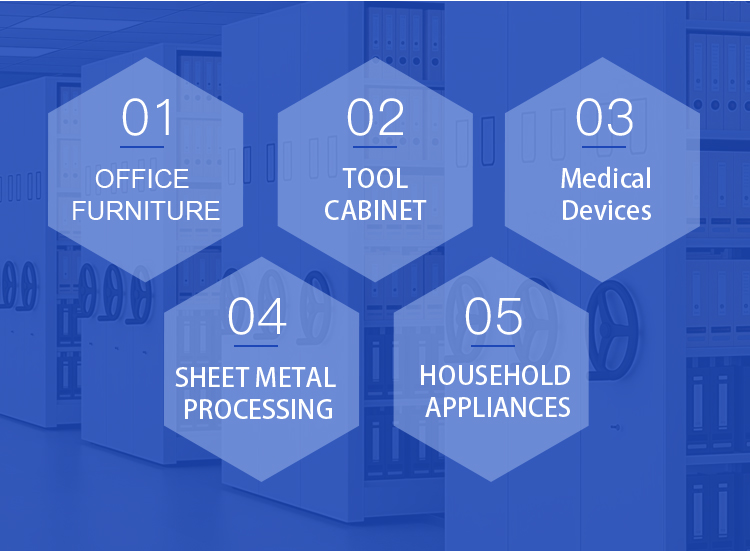

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult