Product advantage

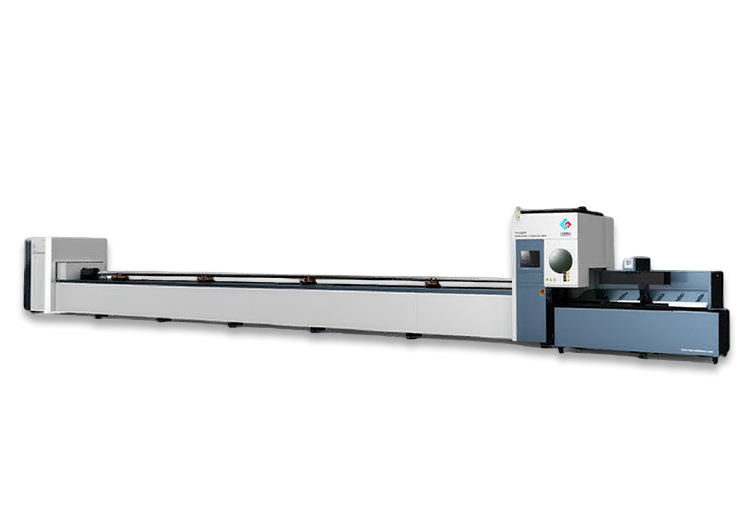

1.Solves the pain point of "single method & poor cutting surface" — Self-designed bevel cutting head supports diversified cutting methods, and the cutting surface is flat, smooth and burr-free, no need for subsequent grinding, improving processing quality and efficiency.

2.Addresses the problem of "unstable clamping & low reliability" — Unique chuck design clamps tubes stably and reliably, avoiding tube deviation during cutting, ensuring cutting precision and operation safety.

3.Resolves the issue of "material waste & high cost" — New zero leftover cutting mode greatly reduces tube waste, achieves a qualitative improvement in tube saving, and lowers enterprises' raw material costs.

2.Addresses the problem of "unstable clamping & low reliability" — Unique chuck design clamps tubes stably and reliably, avoiding tube deviation during cutting, ensuring cutting precision and operation safety.

3.Resolves the issue of "material waste & high cost" — New zero leftover cutting mode greatly reduces tube waste, achieves a qualitative improvement in tube saving, and lowers enterprises' raw material costs.

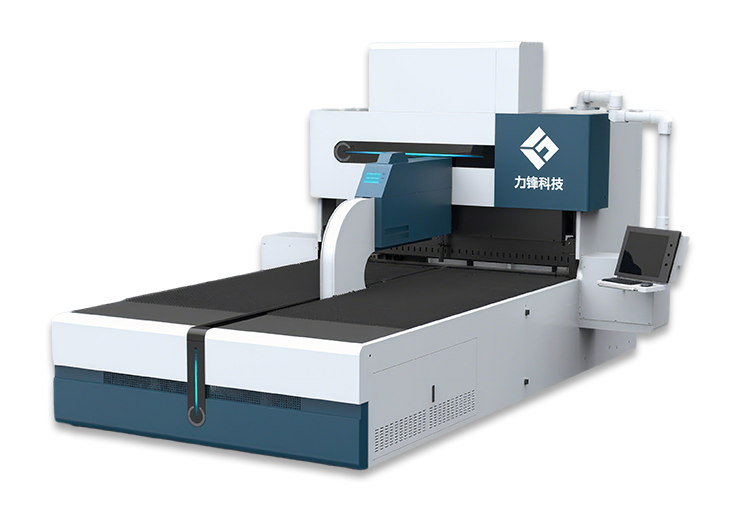

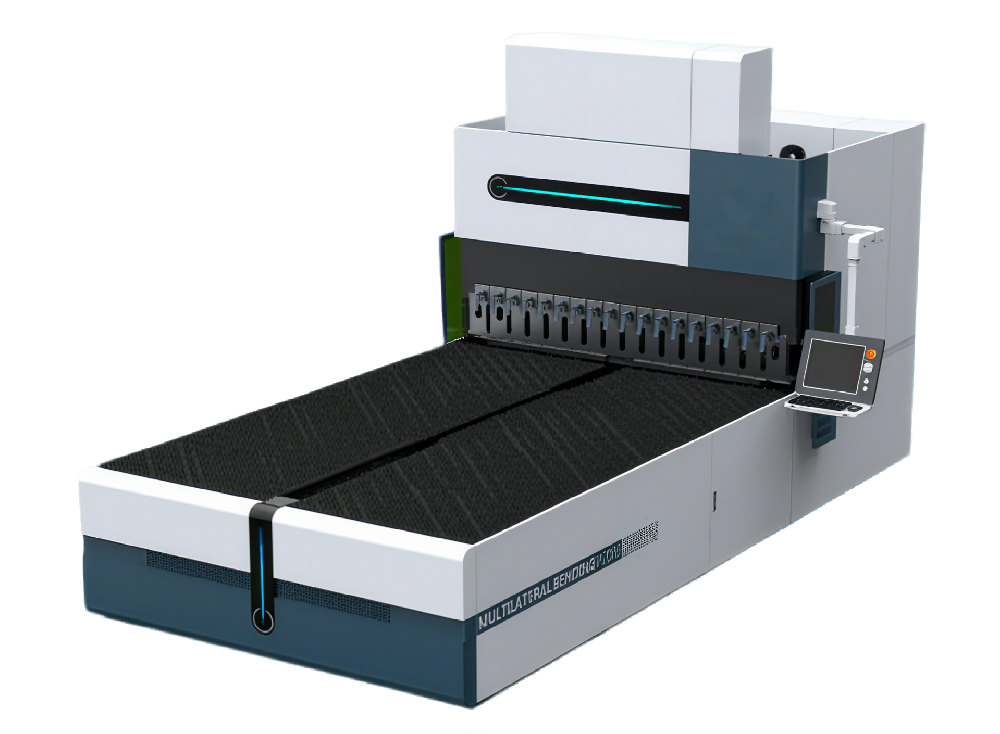

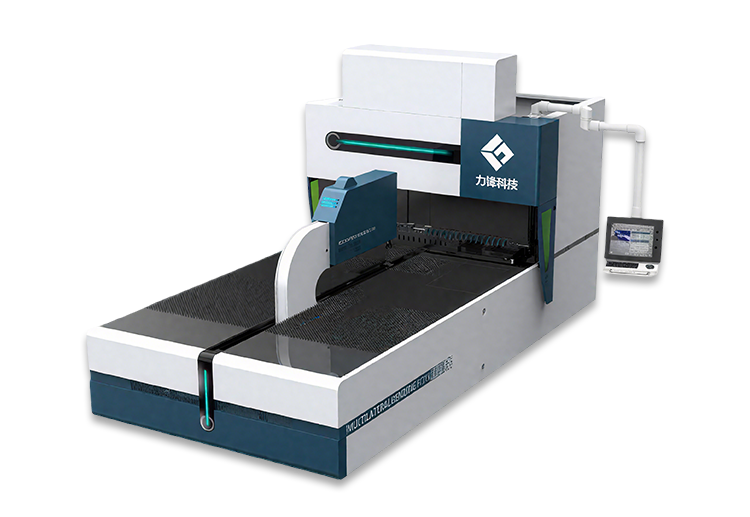

Product show

Product principle

Diversified high-quality cutting — After the CNC system issues instructions, the self-designed bevel cutting head switches cutting methods (such as straight cutting, bevel cutting) according to needs, and the laser is focused on the tube surface to complete cutting, ensuring the cutting surface is flat and burr-free.

Stable clamping and positioning — The unique chuck automatically clamps the tube, fixes the tube position, avoids precision deviation caused by tube shaking during cutting, and provides a stable foundation for precise cutting.

Zero leftover material-saving cutting — The CNC system optimizes the cutting path, adopts the zero leftover cutting mode, makes full use of the tube length, reduces the generation of end waste, maximizes the tube utilization rate and lowers material costs.

Stable clamping and positioning — The unique chuck automatically clamps the tube, fixes the tube position, avoids precision deviation caused by tube shaking during cutting, and provides a stable foundation for precise cutting.

Zero leftover material-saving cutting — The CNC system optimizes the cutting path, adopts the zero leftover cutting mode, makes full use of the tube length, reduces the generation of end waste, maximizes the tube utilization rate and lowers material costs.

Technical specifications

| Machine Model | TMS |

| Pipe Processing Type | Rectangular Pipe, Round Pipe, Angle Steel, C-Section Steel, H-Section Steel |

| Pipe Processing Size | Round Pipe Diameter: 10-450mm; Square Pipe Side Length: 10-420mm |

| Pipe Processing Length | 1000-12000mm |

| Load Capacity per Pipe | 50-200KG |

| Number of Chucks | 2-3个 |

| Maximum Chuck Speed | 90-120r/min |

| Maximum Rapid Traverse Speed | 90-120m/min |

| Maximum Acceleration | 0.8-1.2G |

| Equipment Blanking Direction | L/R |

| Equipment Cutting Method | Conventional Cutting / Bevel Cutting |

| Equipment Blanking Method | Pneumatic Blanking / Servo Blanking |

Hot sale

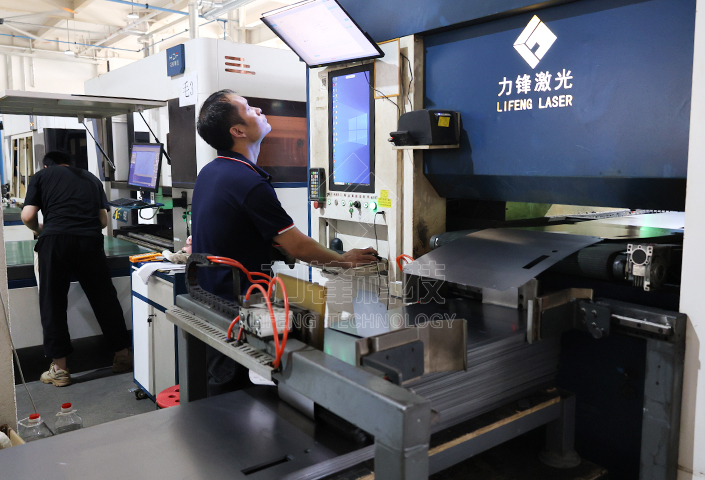

CORE EQUIPMENTCUSTOMER CASE

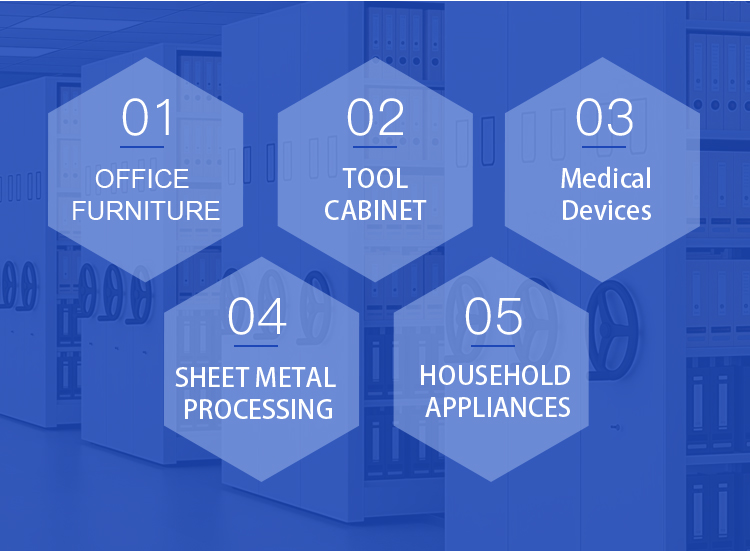

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult