Product advantage

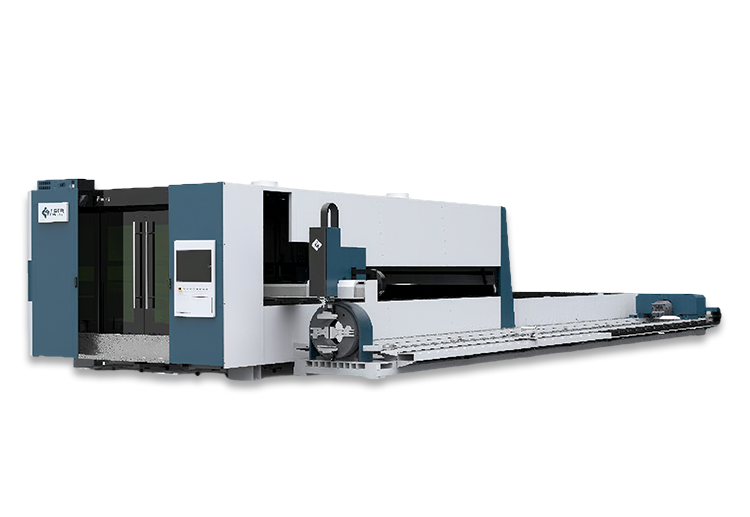

1.Solves the pain point of "single function & high cost" — One machine realizes two processing functions for plates and tubes, no need to purchase additional equipment, effectively reducing production cost; key components from well-known domestic and international brands ensure stable performance.

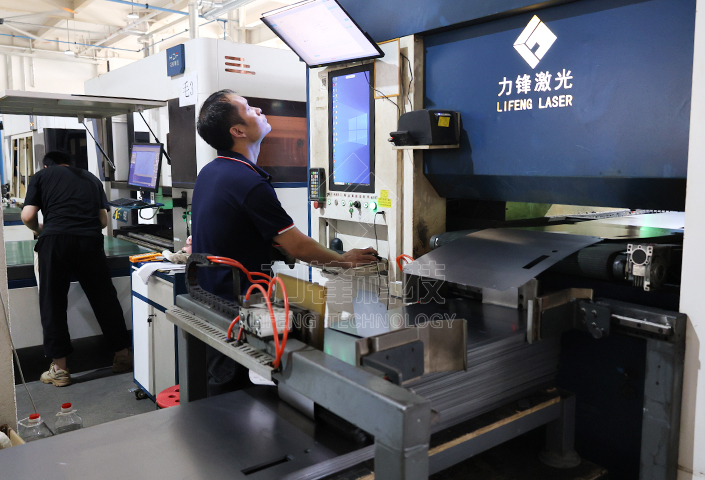

2.Addresses the problem of "low efficiency & high labor cost" — Dual work platforms work alternately, greatly reducing loading/unloading time, with production efficiency increased by more than twice; lowers labor output cost and reduces manual operation intensity.

3.Resolves the issue of "poor protection & weak stability" — Semi-enclosed design provides more effective protection, avoiding potential risks during cutting; gantry structure + aviation aluminum cast beam ensures high machine stability, high strength and rigidity, guaranteeing processing precision.

4.Overcomes the difficulty of "complicated maintenance & high cost" — Maintenance-free optical path design reduces later maintenance workload and cost; the overall reliable structure of the equipment lowers failure probability and reduces downtime loss.

2.Addresses the problem of "low efficiency & high labor cost" — Dual work platforms work alternately, greatly reducing loading/unloading time, with production efficiency increased by more than twice; lowers labor output cost and reduces manual operation intensity.

3.Resolves the issue of "poor protection & weak stability" — Semi-enclosed design provides more effective protection, avoiding potential risks during cutting; gantry structure + aviation aluminum cast beam ensures high machine stability, high strength and rigidity, guaranteeing processing precision.

4.Overcomes the difficulty of "complicated maintenance & high cost" — Maintenance-free optical path design reduces later maintenance workload and cost; the overall reliable structure of the equipment lowers failure probability and reduces downtime loss.

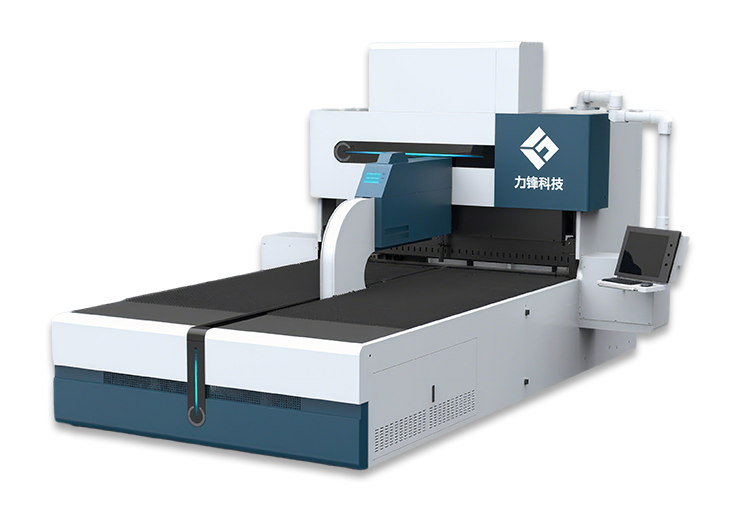

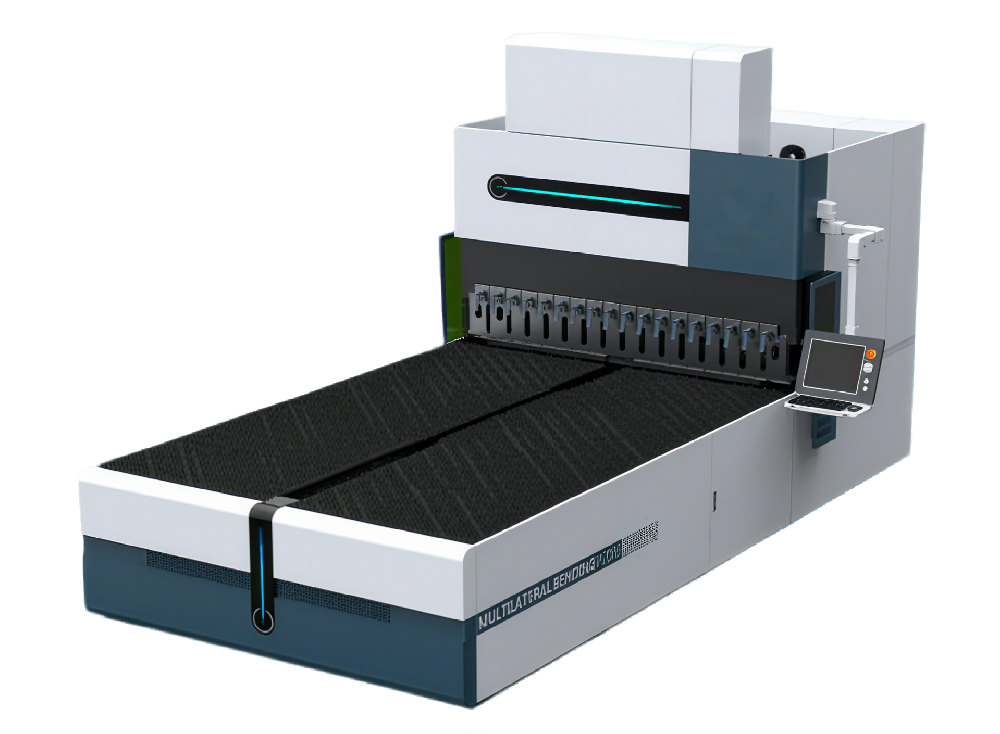

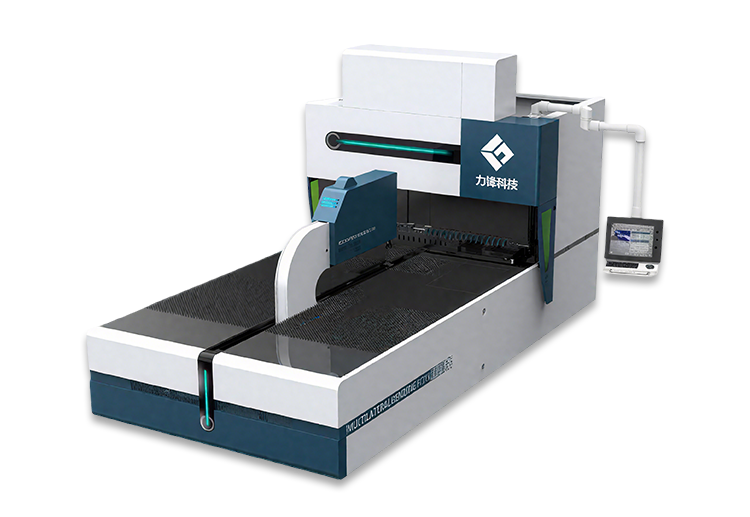

Product show

Product principle

Dual processing for tubes and plates — After the CNC system receives instructions, it switches between plate/tube mode according to processing needs: when processing plates, the workbench bears the plate, and the laser head cuts according to the path; when processing tubes, special fixtures fix the tube, and the laser head adapts to the tube contour to complete cutting, no need to replace equipment.

Efficient operation of dual platforms — Dual work platforms operate alternately: while one platform is cutting, the other completes loading/unloading synchronously, reducing waiting time; the CNC system coordinates platform exchange to realize continuous processing, with efficiency increased by more than twice.

Stable and low-consumption guarantee — Gantry structure and aviation aluminum beam ensure stable equipment operation, avoiding vibration affecting precision; maintenance-free optical path design reduces maintenance links, and semi-enclosed protection isolates risks in real time, forming a "safe-efficient-low-consumption" processing flow.

Efficient operation of dual platforms — Dual work platforms operate alternately: while one platform is cutting, the other completes loading/unloading synchronously, reducing waiting time; the CNC system coordinates platform exchange to realize continuous processing, with efficiency increased by more than twice.

Stable and low-consumption guarantee — Gantry structure and aviation aluminum beam ensure stable equipment operation, avoiding vibration affecting precision; maintenance-free optical path design reduces maintenance links, and semi-enclosed protection isolates risks in real time, forming a "safe-efficient-low-consumption" processing flow.

Technical specifications

| Machine Model | LF-PY-T-6025 | LF-PY-T-8025 | LF-PY-T-10025 | |||

| Cutting Area | 6000x2500mm | 8000x2500mm | 10000x2500mm | |||

| Pipe Processing Type | Rectangular Pipe, Round Pipe, Angle Steel, C-Section Steel, H-Section Steel | |||||

| Pipe Processing Size | Round Pipe Diameter: 10-450mm; Square Pipe Side Length: 10-420mm | |||||

| X-Axis Stroke | 2500mm | |||||

| Y-Axis Stroke | 6000mm | 8000mm | 10000mm | |||

| Z-Axis Stroke | 250mm | |||||

| Minimum Cutting Edge | 1mm | |||||

| Worktable Load Capacity | 6000KG | 8000KG | ||||

| Maximum Positioning Speed | 120m/min | |||||

| Maximum Acceleration | 1.5G | |||||

| Gas Used / Operating Gas | Air / Oxygen / Nitrogen | |||||

Hot sale

CORE EQUIPMENTCUSTOMER CASE

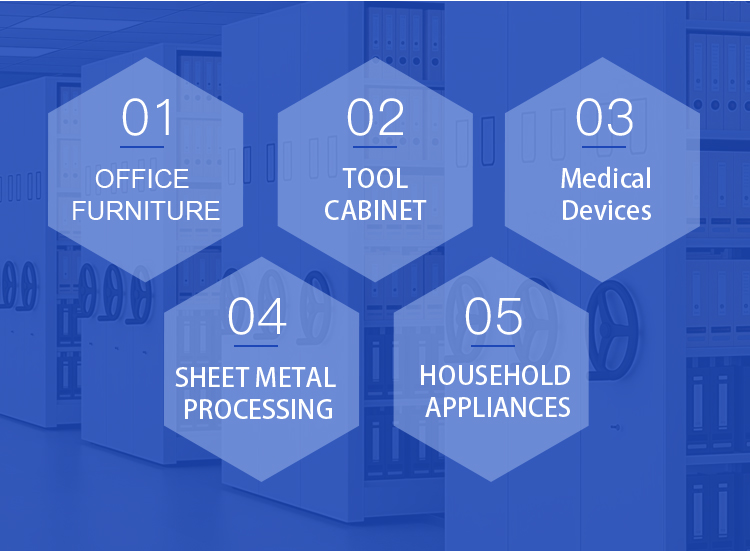

FIELD OF APPLICATION

Copyright reserved©Henan Linfeng Technology Co., Ltd.

Click to consult

Click to consult